In

the ever-evolving landscape of electronic manufacturing, precision, efficiency,

and reliability are paramount. Among the array of cutting-edge technologies

reshaping this industry, ultrasonic welding stands out as a cornerstone method

that continues to revolutionize production processes. As the demand for

smaller, lighter, and more intricate electronic components grows, the function

and importance of ultrasonic welders become increasingly evident.

What is an Ultrasonic

Welder?

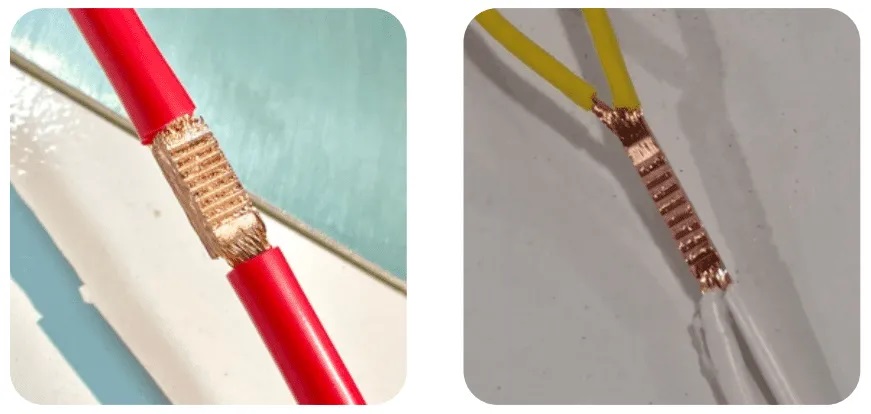

Ultrasonic welding is a bonding technique that

utilizes high-frequency ultrasonic vibrations to create solid-state welds

without the need for additional connective materials such as adhesives or

soldering. This process involves applying high-frequency mechanical vibrations,

typically in the range of 20 to 70 kHz, to the components being joined. These

vibrations generate localized heat and pressure, causing the materials to fuse

together at a molecular level.

The Function of

Ultrasonic Welders in the Electronic Industry:

1. Precision Bonding:

Ultrasonic welders offer unparalleled precision,

enabling manufacturers to create strong and reliable bonds between delicate

electronic components with micron-level accuracy. This precision is crucial in

applications where even the slightest deviation can compromise performance or

functionality.

2. Versatility:

Ultrasonic welding is a versatile process capable

of bonding a wide range of materials commonly used in the electronic industry,

including thermoplastics, metals, and even certain composites. This versatility

allows manufacturers to streamline production processes by eliminating the need

for multiple joining techniques.

3. Rapid Assembly:

With cycle times typically measured in fractions

of a second, ultrasonic welding facilitates rapid assembly of electronic

components, making it ideal for high-volume manufacturing environments. This

speed not only increases productivity but also reduces overall production

costs.

4. Clean and

Efficient:

Unlike traditional bonding methods such as

soldering or adhesive bonding, ultrasonic welding produces clean, precise welds

without the need for additional consumables or post-processing. This results in

a more efficient manufacturing process with minimal waste generation.

The Importance of

Ultrasonic Welders in the Electronic Industry:

1. Miniaturization:

As electronic devices continue to shrink in size,

the demand for precise, reliable bonding techniques becomes increasingly

critical. Ultrasonic welding enables manufacturers to assemble miniature

components with unparalleled accuracy, driving the ongoing trend towards

miniaturization in the electronic industry.

2. Enhanced Product

Performance:

The quality and reliability of electronic devices

heavily depend on the integrity of their internal components. By ensuring

strong, durable bonds, ultrasonic welders play a pivotal role in enhancing

product performance and longevity, ultimately contributing to customer

satisfaction and brand reputation.

3. Cost Efficiency:

In an industry characterized by intense

competition and cost pressures, optimizing manufacturing processes is essential

for maintaining profitability. Ultrasonic welding offers a cost-effective

solution by reducing labor requirements, minimizing material waste, and

streamlining production workflows.

4. Compliance with

Industry Standards:

With stringent regulations governing the safety

and performance of electronic products, manufacturers must adhere to rigorous

quality standards throughout the production process. Ultrasonic welders provide

a reliable method for achieving consistent, high-quality welds that meet or

exceed industry specifications.

Conclusion:

Recent Comments