An electrical cable is much more than a simple conductor. It is an engineered structure composed of multiple layers and components, each with a specific purpose that ensures functionality, safety, and efficiency in any electrical or electronic system. To appreciate the full functionality of an electrical device, it’s essential to understand the core parts of a cable.

Let’s delve into the parts of a cable, the materials commonly used, and how their characteristics are tailored for diverse applications. The functionality of every electrical device, from home electronics to advanced aerospace systems, hinges on a crucial, often overlooked component: the cable.

The main parts of a cable

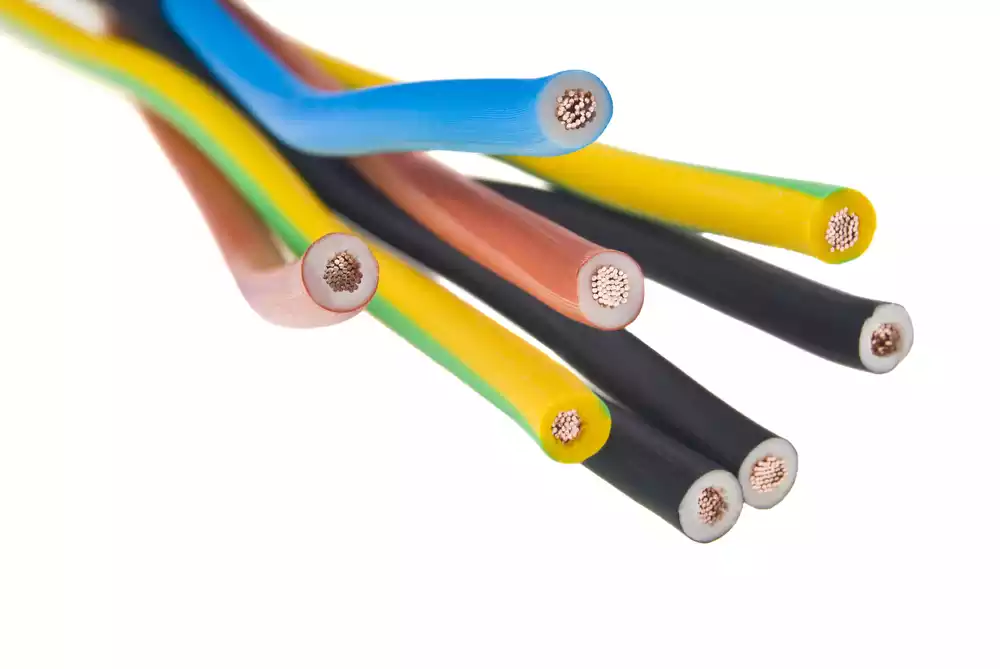

Each cable is designed with a combination of materials that work together. These are the fundamental parts of a cable. The most essential elements are the conductor and the insulation, but they are often complemented by other protective layers that are critical for long-term performance.

- The Conductor: One of the most fundamental parts of a cable, its function is to transport electrical current. The most common material is copper due to its excellent conductivity, ductility, and resistance to corrosion. However, in applications where weight is a critical factor, such as in the aerospace industry or in electric vehicles, aluminum is used. It is lighter and more economical, although it has lower conductivity and requires a larger cross-section to carry the same current as copper.

- The Insulation (Insulator): This layer protects the conductor and prevents the current from dispersing or coming into contact with other surfaces, thus preventing short circuits. Proper insulation is crucial for safety and the integrity of the electrical system. The most common insulating materials include:

- PVC (Polyvinyl Chloride): Economical and flexible, ideal for general-purpose cables in low-voltage applications like household wiring and power cords. It offers basic resistance to fire and abrasion.

- Teflon (PTFE): Known for its excellent thermal and chemical resistance, it is used in extreme industrial environments, high-temperature applications, and medical devices where durability and inertness are required.

- XLPE (Cross-Linked Polyethylene): With outstanding heat and abrasion resistance, it is used in high-voltage cables and demanding industrial settings due to its superior durability and stability.

- The Shielding: This layer, which can be a braided mesh or a metallic foil, protects the electrical signals from electromagnetic interference (EMI) or radio-frequency interference (RFI). This is essential for ensuring data integrity in communication and data cables. It prevents signal degradation caused by external noise sources. This is a key component and one of the most critical parts of a cable for data integrity.

- The Jacket: This is the outermost protective layer that encases the entire cable. Its purpose is to shield the internal components from physical damage, moisture, UV rays, and abrasion. The jacket material varies depending on the use environment, from standard PVC for indoor applications to polyurethane and thermoplastic elastomers (TPE) for harsh industrial settings.

Three common cable types in the Industry

The design and combination of these parts of a cable give rise to a wide variety of cables. Here are three of the most used types in the industry and their applications.

1. Ribbon cable

This cable consists of multiple parallel, flat conductors, giving it a ribbon-like appearance. Its unique design allows for high-density wiring in a small space, making it ideal for compact electronic systems. It is primarily used for low-speed data transmission and is common in computers and printers to connect motherboards to storage drives or display panels.

2 Shielded power cable

These cables are designed to carry electrical power while protecting internal components from electromagnetic interference (EMI). Unlike coaxial cables, which focus on signal integrity, these cables shield the power conductors to prevent their magnetic fields from affecting nearby sensitive cables. They are essential in industrial environments where heavy machinery can generate a lot of electrical noise.

3. Multi-conductor control cable

This type of cable is designed to transmit control signals instead of power. It contains multiple insulated conductors used to control automated machinery or processes. They are found in robotics, industrial automation systems, and control panels where multiple on/off, position, or status signals need to be sent from a controller to actuators or sensors.

The manufacturing and testing process

The manufacturing of cables is a complex process that combines precision engineering with strict quality control, ensuring that each of the parts of a cable is correctly assembled. It begins with the extrusion of the conductor and insulation, followed by the bundling of the wires into their specific configurations (twisted-pair, multi-conductor, etc.). The shielding and jacket are then applied in subsequent steps.

Crucial to this process is quality assurance. Cables undergo rigorous testing to ensure they meet industry standards. These tests include:

- Continuity and short-circuit testing: To ensure every wire is properly connected and there are no accidental connections between wires.

- Insulation resistance testing: To verify that the insulation can withstand the required voltage without breakdown.

- Mechanical tests: To check the cable’s resistance to tensile stress, bending, and abrasion, simulating real-world usage.

Wire harness assembly: A complementary role

The development and manufacturing of cables and their core parts are vast and specialized industries. Industry leaders not only produce high-quality cables but are also experts in wire harness assembly, which is the process of grouping and organizing multiple cables and connectors into a single, custom system. This practice provides an optimized, reliable, and space-saving solution for complex electronic systems.

Understanding the parts of a cable and, more importantly, a wire harness assembly, is the first step to appreciating the complexity and value of these essential components in modern technology. Whether for a simple appliance or an advanced aerospace system, every single one of the parts of a cable has a crucial purpose to ensure optimal performance, a blend of precision engineering and meticulous manufacturing that is vital for our interconnected world.