In the complex and intricate world of modern engineering, where precision and reliability are paramount, understanding the role of a wire harness is crucial. Far from being a mere collection of wires, a wire harness is a sophisticated electrical nervous system specifically designed to connect and manage every electronic component within a device, a vehicle, or a machine.

This blog post will delve into the world of wire harness designs, exploring not just their function, but also the art of customizing them to meet specific needs across various industries without compromising performance. We will discuss design combinations, modern trends, and best practices to ensure any electrical system is organized, efficient, and reliable.

Understanding the blueprint: Design combinations

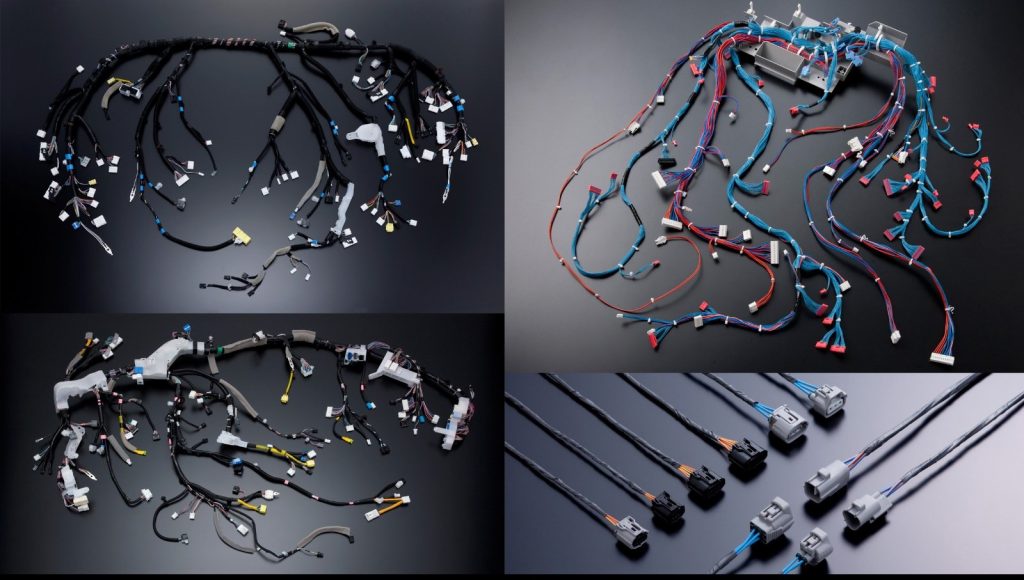

The design of a wire harness is not a one-size-fits-all solution; it is a meticulously planned blueprint tailored to specific applications. The physical layout and organization of the harness are critical for both functionality and aesthetics. Here are some common design combinations across different fields:

- Electronics and consumer products: In devices like smart speakers or drones, a discreet, clean look is desired. This is achieved by routing the harness along existing chassis lines and behind interior panels. The goal is to make the wiring almost invisible while keeping it secure and protected. This approach uses custom-molded conduits and mounting clips to hide the harness without compromising accessibility for future maintenance. The quality of wire harness designs is essential.

- Medical devices: Precision and sterility are non-negotiables in this field. A modular design is often used, breaking down a complex harness into smaller, interconnected modules. Each module can be dedicated to a specific function (e.g., sensor, power, or data). This approach simplifies manufacturing and makes troubleshooting and replacement much easier. If one section fails, you only need to replace that module instead of the entire harness, which is vital in critical equipment like diagnostic machines.

- Automotive and industrial machinery: High-performance and industrial vehicles require harnesses designed to withstand extreme conditions. These wire harness designs prioritize durability and signal integrity. Wires are often braided, shielded, and use materials resistant to high temperatures, vibrations, and corrosive fluids. The routing is meticulously planned to minimize signal interference and ensure precise communication between the control units and the components. The proper wire harness designs are key for safety.

- Hybrid solutions: A common approach is to combine the best elements of these wire harness designs. For instance, a telecommunications system might use a modular design for its main body harness but incorporate specific, high-durability routing for critical external components. This allows for a balance of cost-effectiveness, ease of maintenance, and high performance where it’s most needed.

Key steps in wire harness design

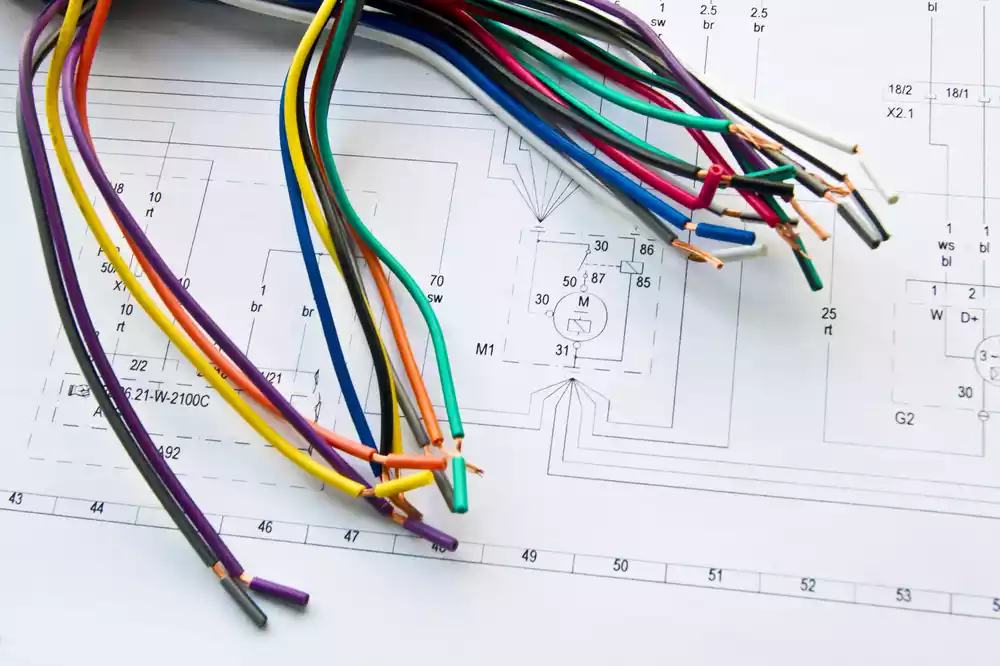

The design of a wire harness is a systematic process that requires precision and attention to detail. Here are the key steps to creating a harness that meets the standards of functionality and durability.

- Requirements gathering: Every design begins with a clear understanding of the project’s needs. This includes the type of signals and power the harness will transport, the environmental conditions (temperature, humidity, vibration), and space requirements.

- Component selection: With clear requirements, the appropriate components are chosen. This includes the wire gauge, insulation material, the type of connectors and terminals, and protective materials like tubing or sleeving.

- Schematic creation: A detailed diagram is generated that shows every connection, the length of the wires, and the location of the connectors. This schematic is the primary blueprint for manufacturing.

- 3D Modeling and prototyping: With 3D modeling software, a digital representation of the harness is created. This allows for verifying the wire routing, managing space, and detecting potential interferences before a physical prototype is manufactured.

Trends and recommendations for modern designs

The field of wire harness designs is constantly evolving with technological advancements. Staying updated on trends and implementing best practices is key to creating a system that is both modern and functional.

1. Miniaturization and weight reduction:

Modern devices, especially electric vehicles, and portable medical equipment, prioritize weight reduction to improve fuel efficiency, range, and portability. This trend has pushed designers to use smaller wires, connectors, and lighter materials like aluminum instead of copper. The challenge lies in maintaining performance and durability with a more compact design.

- Recommendation: Use high-quality, thin-wall insulation materials that offer excellent thermal and mechanical protection without adding bulk.

2. Smart harnesses:

The next generation of harnesses is becoming “smart.” This involves integrating sensors directly into the harness to monitor its own health. These sensors can detect temperature, voltage drops, and even physical damage, providing a predictive maintenance system.

- Recommendation: When designing, consider the possibility of adding sensor integration points. While this might add initial complexity, it can significantly reduce long-term maintenance costs and prevent major failures. The most advanced wire harness designs include this feature.

3. Integration of fiber optics:

With the rise of advanced systems and high-speed data needs, fiber optic cables are being integrated into traditional harnesses. They offer superior speed and are immune to electromagnetic interference, which is crucial for sensitive equipment.

- Recommendation: When dealing with high-bandwidth systems, consider a hybrid harness that combines traditional copper wires for power with fiber optic cables for data. The best wire harness designs often use this.

4. 3D Modeling and prototyping:

Gone are the days of manual, two-dimensional diagrams. Modern wire harness designs are created using sophisticated 3D modeling software that allows for precise routing, interference checks, and virtual prototyping.

- Recommendation: Take advantage of these software tools. They help visualize the final product, identify potential issues early in the design phase, and create highly accurate manufacturing plans. This is a crucial step in the process of wire harness designs.

The importance of proper assembly

A great design is only as good as its execution. This is where wire harness assembly, the process of manufacturing the physical product, becomes critical. Even the most innovative design can fail if the assembly is not meticulous.

Key elements of a proper wire harness assembly include:

- Precision cutting: Wires are cut to exact lengths to prevent excess material that could lead to clutter or signal loss.

- Secure crimping: Terminals are crimped onto the wires with precise force to ensure a strong, reliable electrical connection.

- Protective covering: Wires are bundled and protected with high-quality materials to shield them from heat, abrasion, moisture, and chemicals.

- Rigorous testing: Every harness undergoes extensive testing to check for continuity, short circuits, and proper pin assignments before it is installed.

In conclusion, wire harness designs are a blend of engineering precision and an art form. By understanding the various design combinations, staying updated on modern trends, and prioritizing quality in the wire harness assembly, you can create a system that is not only functional but also a key factor in a product’s long-term reliability and performance.