Choosing the right cabling is as critical as the circuit design itself. A cable is not just a cable; it is the conduit through which energy flows, and the correct type, size, and material can mean the difference between an efficient system and a catastrophic failure. Understanding the different types of electrical cabling is the first step to ensuring the safety and performance of any project, whether it’s a simple home installation or a complex industrial network.

We’ll explore the main types of cabling, their differences, and how factors like structure and use compare to help you select the best option. We’ll also address a topic of critical importance for complex electrical systems: the assembly of multiple cables into a single unit, and why making the right choice here is a strategic decision.

Types of electrical cabling and their differences

Electrical cabling is primarily classified according to its function, structure, and the environment it’s designed for. Below are the most common types, their characteristics, and applications. Of all the types of electrical cabling on the market, it is important to know which one to choose.

1. Single-core cables

- Description: Of all the types of electrical cabling, this is the simplest. They consist of a single metal conductor (usually copper or aluminum) with a protective insulator. They are simple and are used to connect one point to another.

- Differences: They are flexible and easy to handle, ideal for installations where a complex grouping of cables is not required. Their main advantage is flexibility and the ability to be used in different applications.

- Typical Applications: They are common in the internal wiring of electronic equipment, appliances, and in low-power installations where each cable is routed individually. For example, in the cables that go to an outlet or a switch. The importance of types of electrical cabling cannot be overstated.

2. Multi-conductor cables

- Description: Unlike single-core cables, these contain two or more insulated conductors within a single outer jacket. The conductors can be braided or wrapped in parallel.

- Differences: They offer a more organized and compact solution for transmitting multiple signals or power. They reduce clutter and improve the protection of internal cables from external damage.

- Typical Applications: They are the foundation of what are known as specialized cable assemblies. They are used in control systems, equipment power cables, and data communication, such as Ethernet cables or power cables for computers. Their use in the automotive industry and in machinery is vital to organize hundreds of connections into a single package.

3.- Coaxial cables

- Description: Among the types of electrical cabling, the coaxial cable stands out for its unique design. It is designed to transmit radio frequency signals. It consists of an inner conductor, a dielectric insulator, a metal shielding mesh, and an outer jacket.

- Differences: The unique structure of the coaxial with its shielding makes it highly resistant to electromagnetic interference (EMI), which is fundamental to maintaining signal integrity.

- Typical Applications: Television antennas, cable internet connections (broadband), and video security systems (CCTV). They are indispensable in any application where signal quality is a priority. Knowing the right types of electrical cabling is key.

Functionality and development: Keys to a wise choice

The selection of types of electrical cabling not only depends on the type, but also on other critical factors that guarantee safety and performance. The functionality and development of a cable are directly related to:

- The conductor: Most cables use copper due to its excellent conductivity, flexibility, and resistance to corrosion. Aluminum is a lighter and more economical alternative, but it requires a larger gauge for the same current capacity.

- The insulator: The insulating material, such as PVC, polyethylene (PE), or Teflon, is crucial for safety. It must be able to withstand voltage, temperature, humidity, and the chemicals in the environment.

- The size (gauge): The size of the cable, measured in AWG (American Wire Gauge), is vital. A lower gauge indicates a thicker cable with a greater capacity to carry current. Using an insufficient gauge cable can cause overheating and fires.

Sizes of the main cables

The size of a cable is one of the most important factors to consider. Here are the common gauges and their typical uses, which serve as a reference for your projects:

- AWG 22-16 (Small gauges): Used for data signals and low voltage. Common in consumer electronics, control circuits, and telecommunications. For example, inside a television or on an audio cable.

- AWG 14-10 (Medium gauges): Ideal for medium-power applications. Used in lighting wiring, power outlets, and small appliances. They are the standard in many residential and commercial installations.

- AWG 8-1/0 (Large gauges): For high current loads. Found in the main wiring of electrical panels, air conditioning systems, and in the wiring of electric vehicles.

- AWG 2/0 and larger: These are industrial power cables for energy distribution in factories, electrical substations, and large infrastructures. When selecting types of electrical cabling, size matters.

The Importance of wire harness assemblies

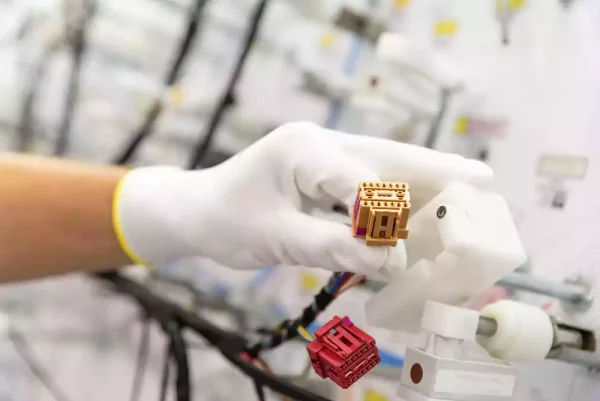

When a project requires the use of multiple cables, organization and protection become a challenge. This is where a wire harness assembly becomes a superior solution.

A harness is a set of wires, connectors, and terminals grouped into a single protective jacket. It is custom-made for a specific application, offering the following advantages:

- Better organization: A harness organizes hundreds of cables into a single neat package, eliminating clutter and optimizing space.

- Greater reliability: The protective jacket shields the cables from abrasion, heat, and chemicals, which extends their lifespan and reduces the likelihood of failures.

- Ease of installation: Being pre-assembled, the harness is installed much more quickly and efficiently than individual cables, saving time and labor costs.

In summary, the choice of electrical cabling should not be taken lightly. By understanding the different types of electrical cabling and their functionality, you can make informed decisions that will directly impact the safety, reliability, and success of your project. Whether you need a simple single-core cable or a complex wire harness assembly, the key is to always choose the right quality and design for the job.