The backbone of modern technology, cable assemblies are more than simple conductors; they are crucial to ensuring power and data flow safely and efficiently. Choosing the correct type of assembly is a critical decision that affects the performance, durability, and cost of a final product. Understanding the different cable assembly types available is fundamental for engineers, designers, and project managers in any industry.

Below, we will explore the most important types of cables, their main applications, the time it takes to manufacture them, and which ones are poised to be the most widely used in the future.

The most important cable types and their function

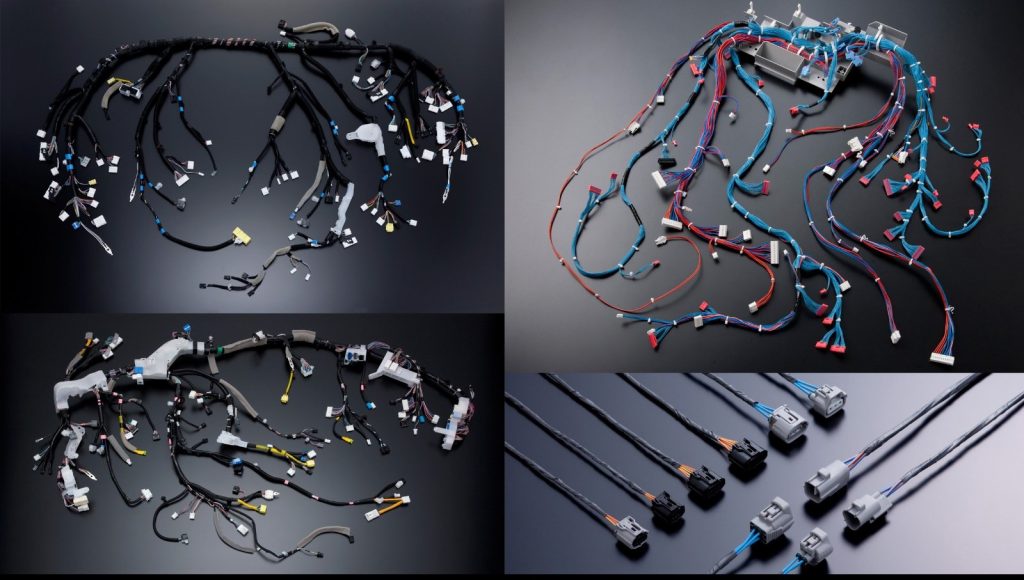

Each application demands a specific cable type. While the list is extensive, these are some of the most vital cable assemblies:

- Ribbon Cables: These cables consist of multiple parallel conductors in a flat, flexible configuration. They are ideal for internal connections that require organization and little space, such as those found in computers and telecommunications equipment.

- Coaxial Cables: Designed with a central conductor surrounded by an insulator, a shield, and an outer jacket. Their unique structure makes them excellent for transmitting high-frequency signals, as in video, radio, and telecommunications equipment, minimizing electromagnetic interference.

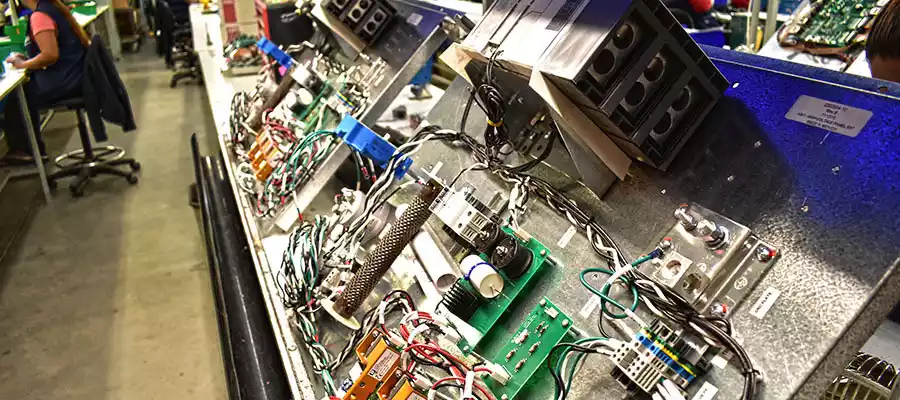

- Molded Cable Assemblies: These assemblies have the connectors and the outer jacket injected directly onto the cable, creating a hermetic seal. They are exceptionally durable and resistant to moisture, dust, and strain, making them perfect for medical, industrial, and heavy-duty consumer devices.

- Fiber Optic Cables: Unlike copper cables, they use glass or plastic filaments to transmit data through light pulses. They offer unparalleled data transmission speed and are immune to electromagnetic interference, making them the primary choice for data centers, telecommunications, and high-speed networks.

What is done with these cables?

The versatility of cable assembly types allows for a wide range of applications across multiple industries. For example, coaxial cables are used in radio frequency equipment, while ribbon cables are the standard for internal connections in computer motherboards. Molded assemblies are found in power cords for appliances and factory equipment where robustness is key. For its part, fiber optics are essential for the operation of high-speed internet and global telecommunications networks.

Manufacturing time: a variable factor

The manufacturing time for a cable assembly is not fixed. It depends on several factors, mainly:

- Design complexity: A simple assembly with few connectors can take a few hours to produce. A complex design with multiple branches and special connectors can take days or weeks.

- Volume: The production of a prototype is slower than that of a large order, where processes are optimized.

- Component availability: The choice of uncommon connectors or materials can significantly extend the delivery time.

- Quality testing: Assemblies for critical environments, such as the medical or aerospace sector, require exhaustive tests that add time to the process.

In general, most orders can take anywhere from a few days to several weeks, depending on the project specifications.

The future: Which cables will be most used?

Looking to the future, three key areas are seen where the demand for cable assemblies will continue to grow exponentially:

- Electric Vehicles (EVs): With the mass adoption of EVs, power and data cables for high-voltage batteries and charging systems will be indispensable. These cables must be lightweight, yet capable of handling large currents and withstanding extreme vibrations and heat.

- Internet of Things (IoT): Cables for IoT devices will need to be smaller, more efficient, and flexible to connect sensors and microcontrollers in tight spaces. Miniaturization and reliability will be the pillars of these assemblies.

- High-speed connectivity (5G and data centers): The expansion of 5G networks and the growth of data centers will demand greater use of fiber optics. These cables will be crucial for transmitting the enormous amount of data generated in tomorrow’s connected world.

At IMA, we understand the importance of these cable assembly types and the need for precision manufacturing solutions, including custom cable assembly in arizona. Our experience and cutting-edge technology allow us to adapt to the demands of your industry and prepare it for the challenges of the future.