In a healthcare environment where precision, reliability, and patient safety are non-negotiable, every component within a medical device plays a critical role. Among these critical elements, medical wire harnesses stand as the unsung heroes, forming the intricate electrical nervous system that enables life-saving equipment to function flawlessly. But what are medical wire harnesses exactly, and why are they so crucial to the accuracy and performance of healthcare devices worldwide?

What are medical wire harnesses?

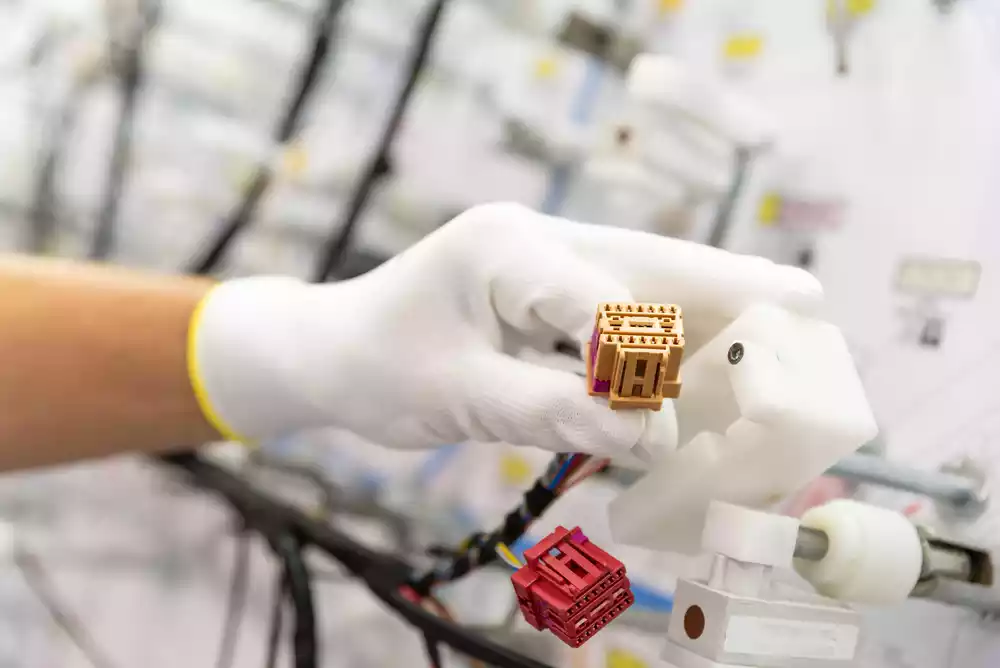

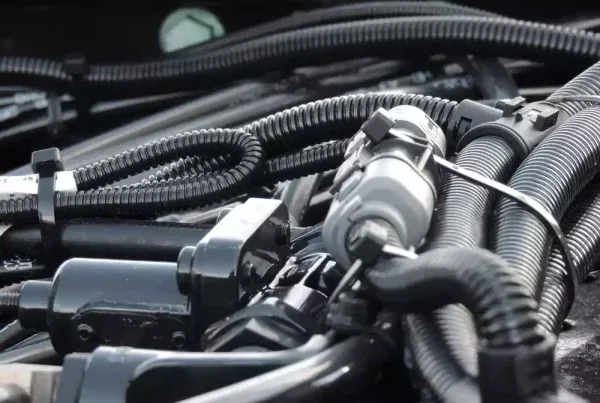

To fully understand what are medical wire harnesses, we must view them as meticulously designed assemblies of electrical wires, terminals, connectors, and protective coverings, organized in a compact and systematic manner. Their primary purpose is to transmit power, signals, and data within medical equipment. Think of them as the nervous system of a medical device: they connect all critical components, ensuring they function seamlessly and without interruption.

From Magnetic Resonance Imaging (MRI) machines and Computed Tomography (CT) scanners to robotic surgical tools, patient monitoring systems, and therapeutic devices like ventilators and infusion pumps, medical wire harnesses are indispensable. Their design is not trivial; they must meet extremely stringent requirements for biocompatibility, sterilization resistance, flexibility, and durability to ensure patient safety and equipment reliability in demanding clinical environments.

Types of medical wire harnesses

The diversity in the application of medical wire harnesses is reflected in their distinct types, designed for specific interfaces and functions within the medical device ecosystem:

- Equipment/Sub-assembly interfaces: These harnesses are found within large and complex medical devices, such as advanced imaging equipment (MRI, gamma cameras). They are an integral part of the original equipment and rarely interact with the end-user, being crucial for internal communication between subsystems.

- Communication interfaces: Responsible for the fast and accurate transmission of medical data. They are used in applications requiring intensive data interfacing, such as surgical robots and telemedicine systems, connecting devices to each other and to networks or servers

- Patient interfaces: These harnesses are designed to interact directly with the patient or medical staff. They must be extremely durable, biocompatible, and easy to clean or dispose of. They include cables for heart monitors (ECG), pulse oximeters, surgical equipment, and portable diagnostic devices.

Within this category, they are subdivided into:

- Long-Life Interfaces: Highly flexible and wear-resistant, used in essential applications such as ECG tests and ultrasound imaging

- Limited-Use Interfaces: Designed to function for a limited time before being replaced due to mechanical wear or exposure to harsh cleaning chemicals. Examples include ICU/CCU monitor cables

- Single-Use Interfaces: Designed to be discarded after a single use, often coming sterilized and packaged in kits. They include catheters, electrosurgical devices, and neural simulator lead sets

In addition to these interface-based classifications, medical wire harnesses can also be categorized by the type of cable used, such as coaxial cables (for high-frequency signals in MRI/CT), ribbon cables (for space-saving in compact systems), and shielded cables (essential for preventing electromagnetic interference in almost all sensitive medical systems)

Key advantages of medical wire harnesses

The adoption of medical wire harnesses in the manufacturing of medical devices offers a series of critical advantages that directly contribute to safety, efficiency, and reliability in the healthcare sector:

- Unparalleled precision and reliability: In the medical field, there is no room for error. Harnesses ensure precise signal transmission and uninterrupted power supply, which is vital for accurate diagnoses and effective treatments

- Space optimization and weight reduction: Modern medical devices are increasingly compact and portable. Harnesses consolidate multiple wires into a single assembly, saving space, reducing weight, and minimizing clutter within the equipment

- Enhanced durability and environmental protection: Medical wire harnesses are designed to protect wires from adverse environmental factors such as abrasion, moisture, vibrations, cleaning chemicals, and electromagnetic interference (EMI/RFI), extending the device’s lifespan.

- Ease of installation and maintenance: Being pre-assembled and organized, harnesses greatly simplify the installation process during manufacturing. Furthermore, their organized nature facilitates troubleshooting and problem-solving during maintenance, reducing equipment downtime.

- Compliance with rigorous standards: The manufacturing of medical wire harnesses adheres to strict international certifications and standards such as ISO 13485 (quality management system for medical devices), IEC 60601-1 (electrical safety), and IPC/WHMA-A-620 (standard for cable and wire harness assemblies), ensuring maximum quality and safety

- Long-Term cost reduction: Although the initial investment in a high-quality harness may be higher, the reduction in assembly errors, increased reliability, and ease of maintenance translate into significant savings over the product’s lifecycle

Global impact on the medical industry

The global medical wire harnesses market is experiencing robust growth, driven by a series of key factors that are transforming the healthcare industry worldwide:

- Increased demand for advanced medical devices: The growing prevalence of chronic diseases, an aging population, and technological advancements are driving unprecedented demand for more sophisticated and high-performance medical devices

- Innovation and miniaturization: The trend towards smaller, portable, and less invasive medical devices requires more complex and miniaturized harnesses, capable of handling a higher density of signals in confined spaces

- Minimally invasive surgical procedures: These procedures, which require highly specialized and reliable equipment, heavily depend on precise and robust wiring harnesses for signal transmission and tool control.

- Emphasis on patient safety and regulatory compliance: Strict regulation in the medical industry demands that all components, including harnesses, meet the highest quality and safety standards. This drives the demand for certified and experienced manufacturers

- Market growth: The global market for medical equipment wiring harnesses is estimated to reach approximately $1.5 billion in 2025, with a projected Compound Annual Growth Rate (CAGR) of 7% until 2033, indicating substantial growth potential. This growth is accelerated by the adoption of Industry 4.0 standards and the electrification of medical equipment.

This market dynamism underscores the strategic importance of medical wire harnesses as an essential component that facilitates innovation and expansion in the healthcare sector, enabling the development of technologies that improve the quality of life for millions of people.

How IMA can help meet your medical wire harness needs

At IMA, with over 29 years of experience in industrial manufacturing and a specialized focus on cable and wire harness assemblies, we understand the critical demands of the medical industry. Our strategic location in Tijuana, a dynamic manufacturing hub, allows us to offer precision and high-quality solutions that meet the unique needs of our clients in the healthcare sector.

We specialize in engineering customized medical wire harnesses solutions that guarantee optimal performance, unwavering durability, and reliability. We don’t just assemble harnesses; we collaborate closely with you, from initial design to final production, ensuring that every product aligns perfectly with your exact specifications.

Our engineering team works directly with clients to address their biggest connectivity challenges, transforming their concepts into tangible and functional creations.

Our manufacturing capabilities include the production of wiring harnesses ranging from simple, streamlined designs to highly complex configurations, always maintaining the most demanding quality standards that the medical industry requires. We implement rigorous quality control at every stage of the process, ensuring that each medical wire harness meets or exceeds industry expectations.At IMA, we are committed to being your trusted partner in the manufacturing of medical wire harnesses, offering customized solutions that not only meet technical requirements but also contribute to the safety and effectiveness of life-saving medical devices. We are ready to simplify your wire harness assembly process and help you bring your innovations to market with confidence.

Recent Comments