Every modern car is a marvel of engineering, a complex symphony of mechanical, electrical, and electronic components working in perfect harmony. While much attention is often given to the engine, transmission, or infotainment system, there’s an unsung hero that makes it all possible: the wiring harness. But what is a wiring harness for a car, exactly? Far from being a simple bundle of wires, it’s the intricate, meticulously organized nervous system that enables every electrical function, from the glow of your headlights to the precise timing of your engine’s fuel injectors.

The core function: Why a wiring harness?

To truly grasp what is a wiring harness for a car, imagine the sheer chaos that would ensue if every single electrical component in a vehicle had its own individual wire running directly to its power source and control unit. The dashboard would be a spaghetti monster of tangled cables, maintenance would be a nightmare, and the chances of electrical faults would skyrocket.

This is where the ingenuity of the wiring harness comes into play. It’s a precisely engineered assembly of wires, terminals, connectors, and protective coverings, designed to transmit power, signals, and data throughout the vehicle in an organized and efficient manner.

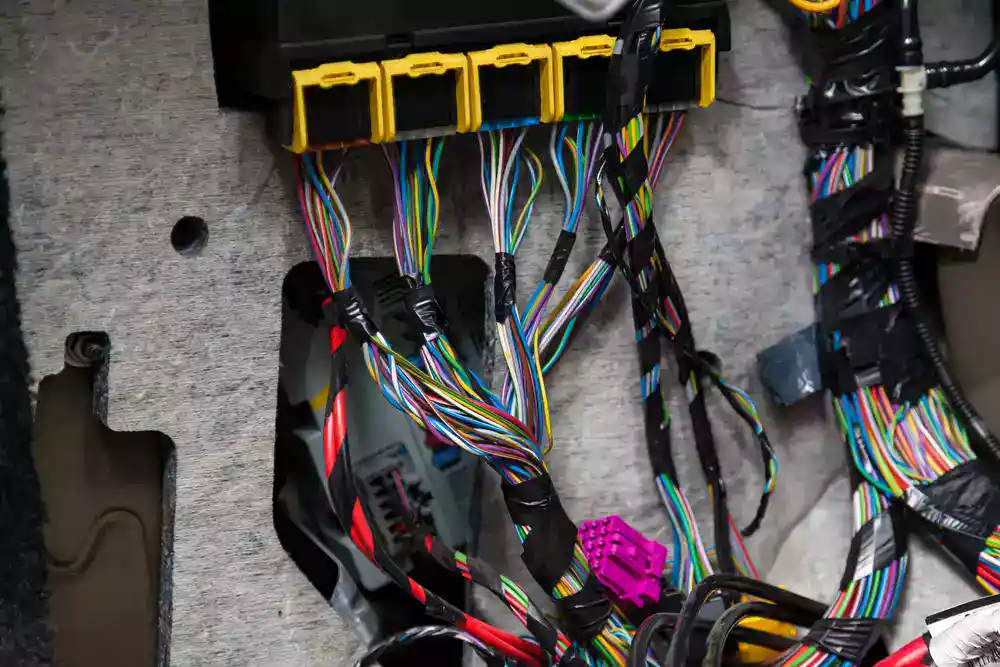

The fundamental purpose of what is a wiring harness for a car is to consolidate and protect the vast network of electrical connections. Instead of hundreds of individual wires snaking through the car, a wiring harness groups them together, often color-coded and labeled, and routes them through specific pathways within the vehicle’s chassis.

This not only simplifies the manufacturing process but also significantly improves reliability and ease of troubleshooting. This structured approach is essential for the longevity and performance of any modern vehicle, preventing common issues like short circuits or signal interference that could compromise safety and functionality.

Anatomy of a wiring harness

Let’s delve deeper into the components that define what is a wiring harness for a car. At its core, it consists of numerous electrical wires, each typically made of copper due to its excellent conductivity. These wires vary in gauge (thickness) depending on the current they are designed to carry. For instance, a wire supplying power to a high-draw component like a starter motor will be much thicker than a wire carrying a signal from a sensor. The selection of the correct wire gauge is critical to prevent overheating and ensure efficient power delivery.

Beyond the wires themselves, terminals are crucial. These are small metal connectors crimped onto the ends of the wires, allowing them to be securely connected to other components or to other parts of the harness. These terminals then fit into connectors – plastic housings that often contain multiple terminals, creating a robust and often weatherproof connection point.

The design of these connectors is vital; they must withstand vibrations, temperature fluctuations, and sometimes even moisture without compromising electrical integrity. Modern connectors are often designed with locking mechanisms to prevent accidental disconnections and seals to protect against environmental ingress.

Another key aspect of what is a wiring harness for a car is its protective covering. Wires within a harness are typically bundled together using various materials like electrical tape, corrugated tubing (split loom), braided sleeves, or even custom-molded conduits.

This protection serves multiple purposes: it shields the wires from abrasion, heat, moisture, and chemicals, preventing damage that could lead to shorts or open circuits. It also helps to maintain the harness’s shape and integrity, preventing tangling and ensuring proper routing. The choice of protective material depends on the specific environmental conditions the harness will face, such as engine bay heat or exposure to road debris.

The manufacturing process

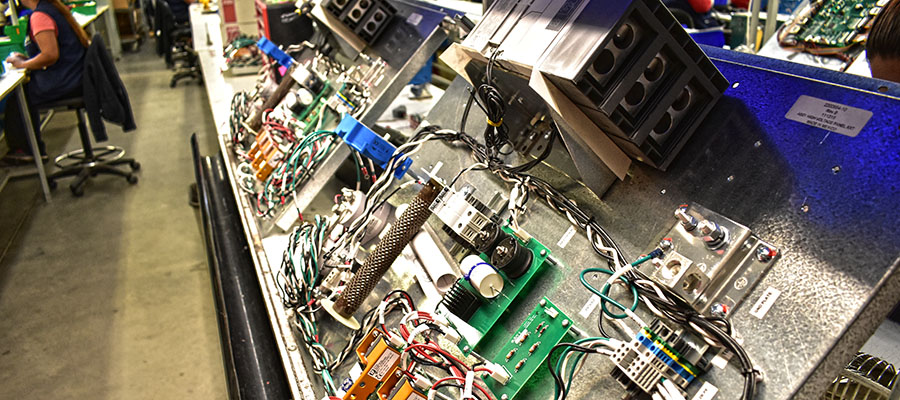

The manufacturing process of what is a wiring harness for a car is surprisingly complex and often involves a high degree of automation combined with skilled manual labor. It begins with cutting wires to precise lengths, followed by stripping the ends and crimping terminals. These pre-processed wires are then routed onto specialized boards or jigs that replicate the exact layout of the harness within the vehicle. This “formboard” method ensures that each wire is placed in its exact position, with the correct length and routing, mirroring the final installation in the car.

Workers then meticulously insert the terminals into the correct connector housings, apply protective coverings, and secure the bundles. This stage requires significant precision to avoid errors that could lead to electrical malfunctions. Quality control is paramount at every stage to ensure continuity, correct pin assignments, and proper insulation.

Automated testing equipment is often used to verify every connection and ensure there are no shorts or open circuits, guaranteeing that the finished wiring harness meets stringent automotive standards. This rigorous process is a testament to the importance of the wiring harness in vehicle functionality.

Diverse applications within a vehicle

So, when considering what is a wiring harness for a car, it’s important to understand its widespread application throughout the vehicle. There isn’t just one “master” harness; rather, a car contains multiple specialized harnesses, each dedicated to a particular area or system. For example, there’s typically an engine harness that connects to sensors, injectors, and ignition coils, managing the critical functions of the powertrain. A body harness manages lighting, power windows, central locking, and other cabin electrical systems.

Furthermore, a dashboard harness is responsible for instrumentation, infotainment systems, and climate control. There are often separate harnesses for doors, seats (especially with power adjustments and heating), and even exterior lighting, ensuring that every electrical component has a dedicated and protected pathway.

These various harnesses often connect to each other at key junction points, forming a cohesive electrical network. The modular design of these harnesses simplifies both manufacturing and maintenance, allowing for easier replacement or repair of specific sections.

Evolution and future trends

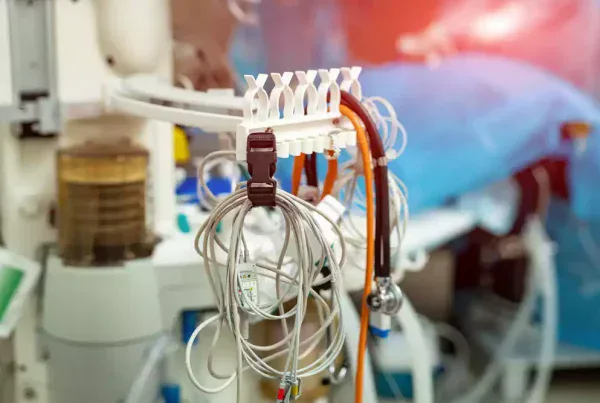

The evolution of automotive technology has significantly impacted what is a wiring harness for a car. As vehicles become more sophisticated with an ever-increasing number of electronic control units (ECUs), sensors, and entertainment features, the complexity of wiring harnesses has grown exponentially.

Modern vehicles might contain miles of individual wires and hundreds of connection points. This escalating complexity underscores the critical role of robust design and manufacturing in ensuring vehicle reliability and performance. The demand for higher data transfer rates for features like autonomous driving and advanced infotainment systems is pushing the boundaries of traditional copper wiring.

Furthermore, the materials used in wiring harnesses are continually evolving. There’s a constant drive to reduce weight for improved fuel efficiency, leading to the adoption of lighter gauge wires and more compact connectors. The integration of fiber optics for high-speed data transmission, particularly for advanced driver-assistance systems (ADAS) and infotainment, is also becoming more prevalent, adding another layer of complexity to what is a wiring harness for a car.

These advancements demand even greater precision in manufacturing and assembly to maintain signal integrity and ensure the seamless operation of cutting-edge automotive technologies. The future will likely see even more integration and miniaturization.

In essence, what is a wiring harness for a car is the unsung hero that orchestrates every electrical function, from the simplest indicator light to the most complex engine management system. It’s a meticulously designed and manufactured component that ensures power and data flow seamlessly, contributing significantly to the safety, reliability, and overall performance of any vehicle.

Its role is indispensable, providing the critical pathways for communication and power distribution that bring a car to life. The intricate process of manufacturing these vital components often culminates in a precise and highly efficient wire harness assembly.

Recent Comments