In the intricate world of automotive engineering, where precision and reliability are paramount, understanding each component’s role is crucial. Among the myriad parts that make a vehicle function, the engine harness stands out as a critical, yet often overlooked, element. But what is an engine harness? Far from being a mere collection of wires, it is the sophisticated electrical nervous system specifically designed to connect and manage every sensor, actuator, and electronic control unit (ECU) within the engine compartment. It ensures the seamless flow of power, signals, and data, allowing the engine to operate efficiently and reliably.

What is an engine harness?

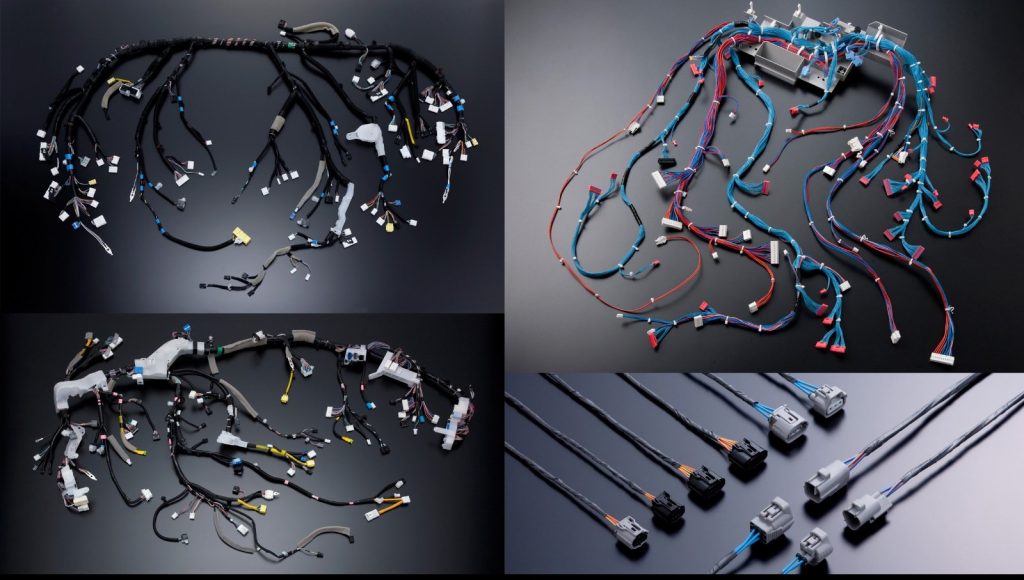

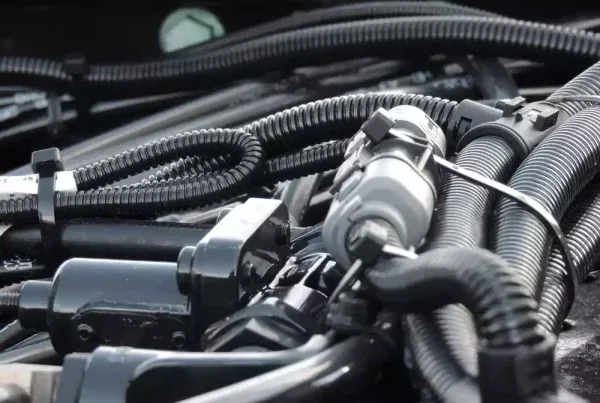

To fully understand what is an engine harness, it is essential to visualize it as a complex and organized assembly of electrical wires, terminals, connectors, and protective coverings. Its primary function is the transmission of electrical power and the communication of control information between the Engine Control Unit (ECU) and the various engine components. This includes elements as varied as fuel injectors, ignition coils, oxygen sensors, temperature sensors, pressure sensors, and many others that are vital for engine performance.

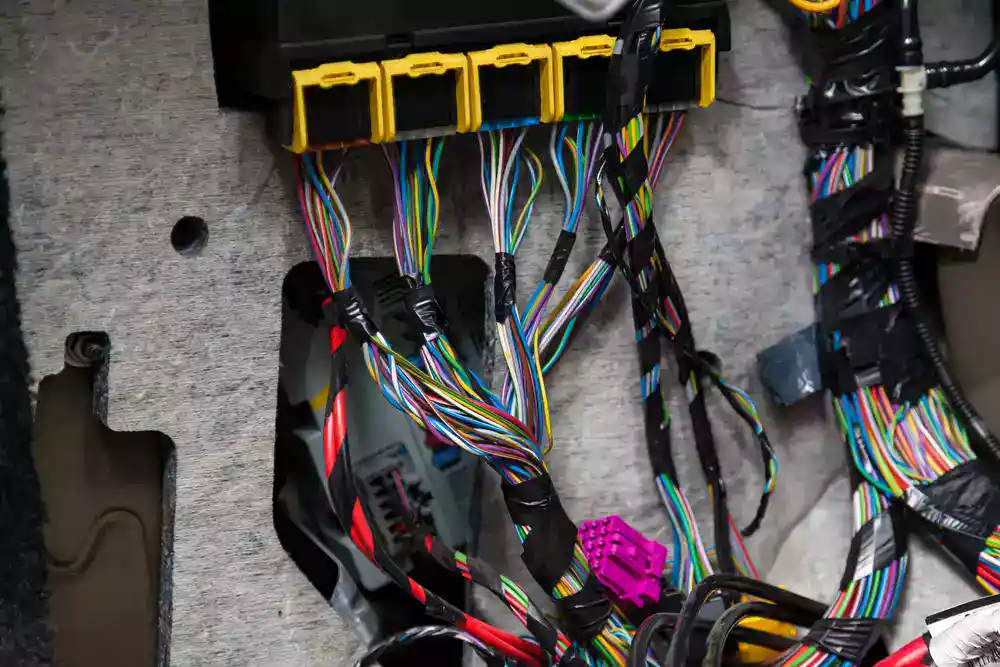

Without a meticulously designed and manufactured engine harness, the engine compartment would be a tangled mess of loose wires, susceptible to short circuits, signal interference, and electrical failures. The harness consolidates these wires into an organized and protected package, which not only simplifies factory assembly but also facilitates future diagnosis and repair. It is, in essence, the electrical backbone that allows the engine’s brain (the ECU) to communicate with all its vital organs.

The critical role of the engine harness

The engine harness plays an indispensable role in the functioning of a modern vehicle. Its importance lies in the transmission of critical data and the powering of components that are fundamental to engine performance, efficiency, and emissions. For example, oxygen sensors send exhaust gas data to the ECU via the harness, allowing the ECU to adjust fuel injection to optimize combustion and reduce emissions.

Similarly, the harness supplies power to the spark plugs through the ignition coils, initiating the combustion process.

A failure in the engine harness can have serious consequences, ranging from poor engine performance and increased fuel consumption to starting failures or even engine stalling while driving. Interrupted signals or inconsistent power supply can lead to dashboard error codes and, ultimately, costly repairs. Therefore, the integrity and quality of an engine harness are directly proportional to the reliability and safety of the vehicle.

Key components of an engine harness

An engine harness is composed of a variety of elements, each with a specific function to ensure efficient and safe electrical transmission. The main components include:

- Electrical wires: Generally made of copper, they vary in gauge (thickness) depending on the current they need to carry. Thicker wires are used for high-current components (like the starter motor), while thinner ones are for low-voltage signals. The choice of insulating material (PVC, Teflon, silicone) is crucial to protect against heat, moisture, and abrasion

- Terminals: Small metal connectors crimped onto the ends of the wires. They allow for a secure and conductive connection to other components or within the connectors

- Connectors: Plastic housings that contain multiple terminals, creating robust and often weather-sealed connection points. Their design is vital to withstand vibrations and temperature changes

- Protective coverings: Materials such as electrical tape, corrugated tubing (loom), braided sleeves, or custom-molded conduits. They protect the wires from abrasion, heat, moisture, chemicals, and electromagnetic interference, maintaining the harness’s shape and integrity

- Fasteners and brackets: Clips, zip ties, and brackets that secure the harness in place within the engine compartment, preventing excessive movement and contact with hot or moving parts

- Fuses and relays: Although often located in separate boxes, the engine harness connects directly to these boxes to protect circuits from electrical overloads

Types of engine harnesses

While the term “engine harness” specifically refers to the engine’s harness, it’s important to recognize that variations and classifications exist. There isn’t one universal type; instead, they adapt to the specific needs of each vehicle model and generation.

- OEM (Original Equipment Manufacturer) harnesses: These are harnesses designed and manufactured by the original supplier for a specific vehicle model. They are made to fit perfectly and meet all the automaker’s specifications. They are the most reliable option for replacements.

- Aftermarket harnesses: Manufactured by companies that are not the original vehicle supplier. They may offer customization options or be more economical, but quality and compatibility can vary. It is crucial to choose reliable suppliers to avoid performance issues.

- Harnesses by engine generation/model: Harnesses vary significantly between different engine models (e.g., 4-cylinder vs. V8 engines, gasoline vs. diesel engines) and between different generations of the same engine, due to changes in technology, sensors, and component placement.

- Harnesses for electric vehicles (EVs): With the rise of electric vehicles, engine harnesses (or, more precisely, electric powertrain harnesses) are evolving to handle high voltages and high-speed data communication requirements for battery and electric motor management. These harnesses are more complex and require advanced materials for safety and efficiency.

The manufacturing and testing process

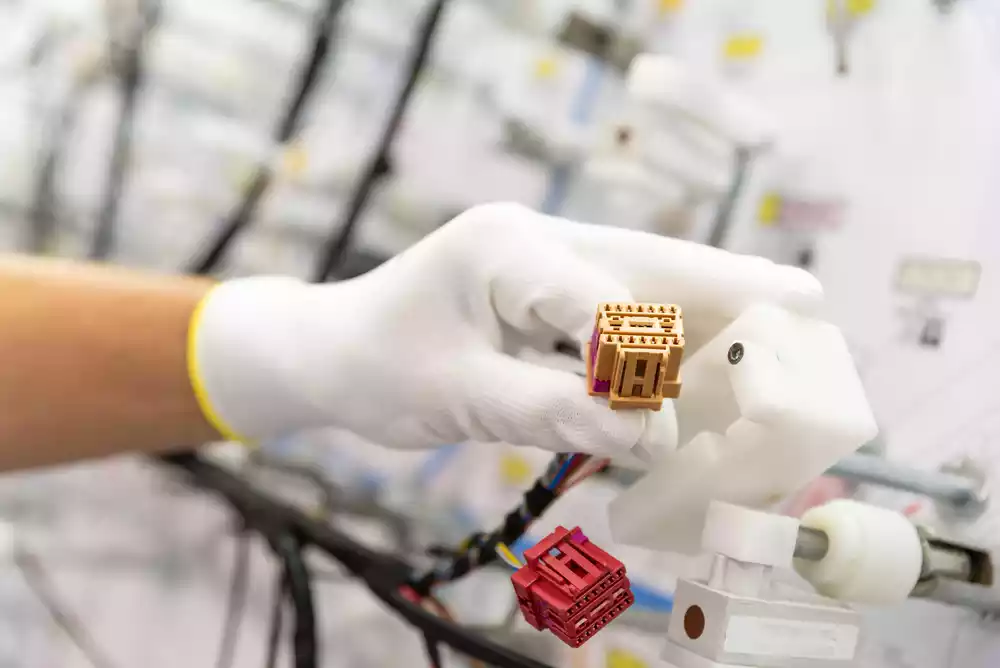

The creation of an engine harness is a high-precision manufacturing process that combines advanced automation with skilled manual labor. It begins with the detailed design of the harness, often using CAD software, which generates schematic diagrams and assembly plans.

- Wire cutting and stripping: Wires are cut to exact lengths, and their ends are stripped using automated machines for high accuracy and speed.

- Terminal crimping: Metal terminals are crimped onto the ends of the wires. This is a critical operation that requires precise force to ensure a strong electrical and mechanical connection without damaging the wire.

- Connector insertion: Wires with crimped terminals are inserted into the connector housings according to the assembly diagram.

- Assembly on formboards: Wires and connectors are meticulously placed and routed on formboards that replicate the exact shape and dimensions of the harness in the vehicle. This ensures that each branch of the harness has the correct length and routing, mirroring the final installation in the car.

- Protection application: Protective coverings (tape, tubing, etc.) are applied to secure the wire bundles and protect them from environmental factors.

- Quality control and testing: Each engine harness undergoes rigorous electrical testing to verify continuity, resistance, absence of short circuits, and correct pin assignment. Automated testing equipment is used to ensure the harness meets strict automotive standards before leaving the factory.

Advantages of using a dedicated engine harness

The implementation of a dedicated engine harness offers multiple benefits that are fundamental to vehicle performance and durability:

- Improved reliability: By grouping and protecting wires, the likelihood of damage, short circuits, or loose connections is drastically reduced, resulting in a more reliable electrical system less prone to failures.

- Organization and space efficiency: It consolidates hundreds of individual wires into an organized package, freeing up space in the engine compartment and facilitating access to other components for maintenance.

- Ease of installation and maintenance: During vehicle assembly, a pre-fabricated harness is installed much faster and more efficiently than individual wires. For maintenance, color-coding and labeling of wires within the harness simplify identification and troubleshooting.

- Environmental protection: Protective coverings shield the wires from extreme heat, moisture, engine fluids, vibrations, and abrasion, extending the lifespan of the electrical system.

- Optimal performance: By ensuring clean signal transmission and consistent power supply, the engine harness allows the ECU and sensors to operate with maximum precision, leading to better fuel efficiency, higher power, and lower emissions.

- Long-Term cost reduction: Although initial manufacturing is complex, the increased reliability and ease of maintenance of a quality harness can significantly reduce repair costs and vehicle downtime over its lifespan.

Common problems and maintenance

Despite its robustness, an engine harness can suffer wear and tear over time or due to adverse conditions. Common problems include:

- Worn or frayed wires: Abrasion from vibration or contact with sharp edges can damage wire insulation, leading to short circuits.

- Loose or corroded connectors: Exposure to moisture or chemicals can cause corrosion on terminals, resulting in intermittent connections or signal loss.

- Heat damage: Excessive engine heat can degrade wire insulation, making them brittle and prone to failure.

- Fluid damage: Leaks of oil, coolant, or fuel can deteriorate harness materials.

- Overload: Adding incompatible electrical accessories can overload the harness, causing overheating and damage.

Regular visual inspection of the engine harness for signs of wear, fraying, or corrosion is crucial. Ensuring the harness is properly secured and away from heat sources or moving components can extend its lifespan.

Evolution and future of engine harnesses

The evolution of automotive technology has profoundly impacted the complexity and design of the engine harness. As vehicles become more sophisticated, with more ECUs, sensors, and advanced driver-assistance systems (ADAS), the demand for more advanced harnesses capable of handling higher volumes of data at faster speeds has grown exponentially.

Future trends include:

- Weight reduction: To improve fuel efficiency and range in EVs, lighter materials like aluminum are being explored instead of copper for wires, and more compact connectors

- Fiber optic integration: For high-speed data transmission required by ADAS and infotainment systems, fiber optics are becoming more common, adding a new layer of complexity to harness manufacturing

- Modularity and miniaturization: Modular designs facilitate assembly and repair, while component miniaturization allows for smaller and lighter harnesses

- Smart harnesses: The integration of sensors within the harness itself to monitor voltage, temperature, and data flow could enable predictive diagnostics and proactive maintenance, anticipating problems before they occur

- Sustainability: The industry is moving towards using more eco-friendly materials and sustainable manufacturing processes for harnesses

The engine harness is much more than a simple bundle of wires; it is the vital nervous system that allows a vehicle’s engine to operate with precision, efficiency, and reliability. From transmitting critical signals to supplying power to essential components, its high-quality design and manufacturing are fundamental to the overall performance and safety of the automobile.

As automotive technology continues to advance, the engine harness will continue to evolve, adapting to the demands of increasingly intelligent and electrified vehicles, demonstrating the ongoing importance of precise wire harness assembly.

Recent Comments