Cable assembly is the nervous system of modern technology. Its demand is not only an indicator of industrial health but also a barometer of innovation. The consumer electronics (CE) industry is one of the most dynamic and fastest-growing sectors globally. From smartphones and smart home devices to high-performance virtual reality and gaming equipment, the sector is expanding at a rapid pace.

However, the secret behind the functionality, speed, and portability of these devices lies not only in advanced chips but also in the connectivity components that bind them together: consumer electronics cables.

1. Why is this industry experiencing so much growth?

The consumer electronics sector maintains its momentum thanks to three key factors:

A. Home digitalization (IoT and smart home)

The mass adoption of connected devices (IoT), such as smart thermostats, security cameras, and voice assistants, creates interconnected ecosystems. These devices require discreet, highly durable cables that allow for the constant transmission of data and power. The convenience and efficiency offered by these smart homes continually drive demand.

B. Miniaturization and enhanced performance

The modern consumer demands smaller, lighter, and more portable devices, while simultaneously requiring superior power and speed (e.g., 4K/8K displays, fast charging). This pressures manufacturers to use consumer electronics cables that are increasingly thinner and more flexible and feature advanced shielding to handle greater data flows without interference or overheating.

C. The technology renewal cycle

Driven by constant innovation (the launch of new generations of smartphones, video game consoles, and wearables), the life cycle of many CE products is short. This ensures a continuous flow of production and demand for components, including consumer electronics cables.

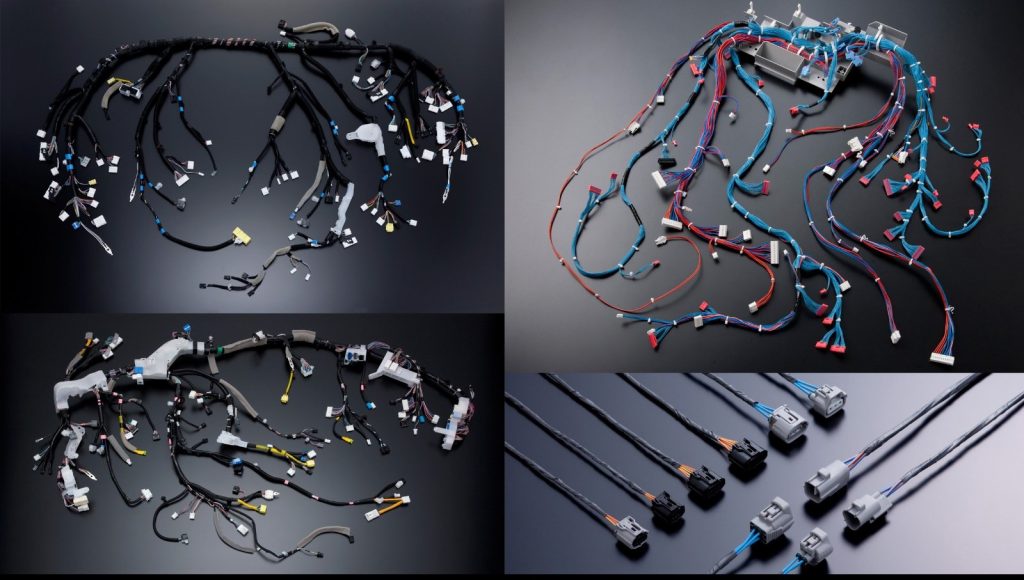

2. The main consumer electronics cables used

Consumer Electronics utilizes a wide spectrum of cables, but the most critical ones focus on speed, miniaturization, and power/data transmission:

| Cable Category | Primary Function | CE Application | Design Requirements |

| High-Speed Cables (HDMI, DisplayPort, USB 3.x/4) | Transmission of high-bandwidth data and video (e.g., 4K/8K). | TVs, monitors, consoles, virtual reality. | Low latency, high shielding, robust and precision connectors. |

| Flexible Flat Cables (FFC/FPC) | Internal connection of Printed Circuit Boards (PCBs). | Smartphones, cameras, laptops (screen to motherboard). | Ultra-thin, high pin density, high flexibility. |

| Coaxial Cables (Micro-Coax) | Transmission of radio frequency (RF) or video signals. | Antenas, Wi-Fi/Bluetooth modules, GPS equipment, drones. | High signal fidelity, superior shielding, small diameter. |

| DC Power and Fast Charging Cables | Power supply to devices and batteries. | Laptop chargers, power banks, USB-C PD devices. | Capacity for high currents (low AWG), resistance to flex cycles. |

The importance of the industry: This industry not only generates billions of dollars but also serves as the foundation for modern communication, remote work, entertainment, and education. Cables are the conduits that allow this functionality to be realized reliably and efficiently.

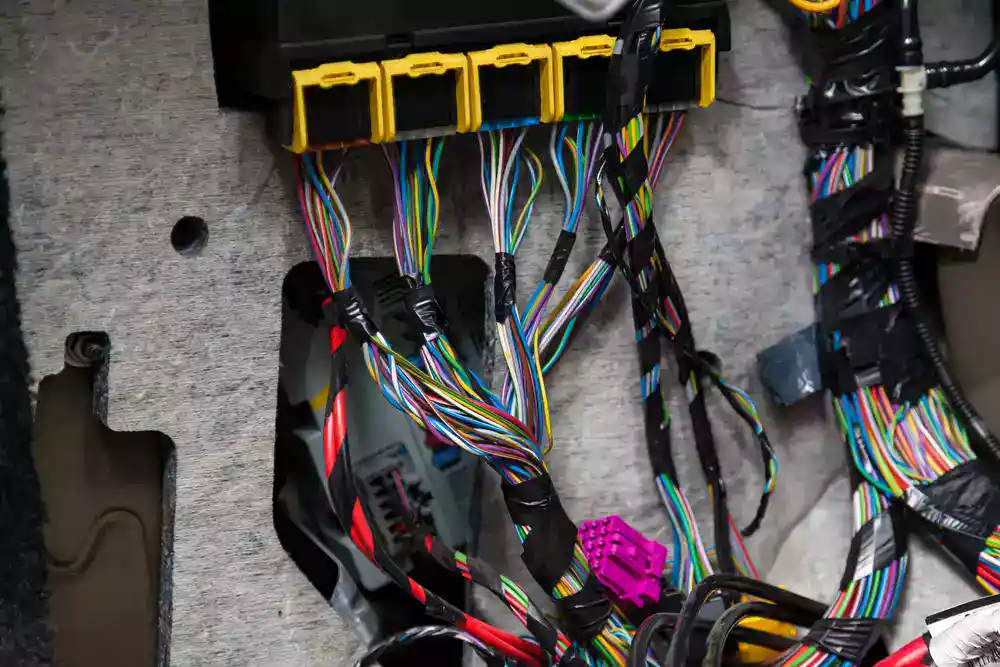

3. Advanced Cable Assembly Solutions

Cable assembly is not a simple process, especially for consumer electronics, where the margin for error is minimal due to strict tolerances and reduced sizes.

How consumer electronics cables drive growth

The continuous growth of the CE sector relies directly on the ability of assembly manufacturers to solve challenges such as:

- Reliability in Volume: Producing millions of FFC or high-speed assemblies with a near-zero failure rate.

- Fast Charging Support: The new generation of consumer electronics cables must be able to support up to 240W (USB-C Power Delivery 3.1) without compromising safety.

- Integration into Compact Systems: The assembly must be precise enough to fit perfectly into increasingly thin device enclosures.

The importance of IMA in this process

In high-growth manufacturing and logistics regions, the capability of a partner like IMA Manufacturing to offer specialized cable assembly in Nevada is a strategic factor for high-tech manufacturing support.

IMA becomes a key player by providing:

- Proximity and Speed: Being strategically located in Nevada, they can reduce transit times and respond quickly to changes in the supply chain—a critical factor for the short CE product lifecycle.

- Value-Added Services: Offering not only assembly but also overmolding to protect connection points and sealing, ensuring durability and resistance to water/dust, common requirements in modern Consumer Electronics.

- Strict Compliance (IPC/UL): Ensuring that all consumer electronics cables and assemblies comply with quality and safety standards (UL, IPC/WHMA-A-620), which is fundamental for global brands.

The future of consumer technology depends on excellence in connectivity. The industry is growing, driven by innovation and digitalization, but this expansion is only possible with exceptional-quality consumer electronics cables.

For companies looking to scale production and guarantee the reliability of their devices, partnering with assembly experts like IMA is essential to transforming a product design into a massive commercial success.