At the heart of every piece of advanced technology, from electric vehicles and medical diagnostic equipment to communication systems and precision machinery, lies a complex network of wires. This electrical “nervous system,” known as a cable or wire harness assembly, is a critical component. It is not merely a means of transporting energy, but a guarantor of signal integrity and operational safety.

The failure of a single cable assembly can paralyze a production line, compromise end-user safety, or, at best, require costly technical interventions. Therefore, understanding and executing rigorous quality control for cable assemblies is not an optional step in manufacturing; it is the cornerstone upon which product reliability and brand reputation are built.

What are the industry standards for cable quality?

For a cable assembly to be deemed fit for installation in critical equipment, it must comply with a set of international standards that dictate the criteria for design, manufacturing, and acceptance. These standards serve as the universal language of quality in this sector:

IPC/WHMA-A-620 This is the global benchmark standard. Jointly published by the IPC (Association Connecting Electronics Industries) and the WHMA (Wire Harness Manufacturer’s Association), the A-620 is an exhaustive document detailing the requirements and acceptability of cable assemblies, wire harnesses, and conductor bundles. It covers everything from visual criteria for crimping and soldering to routing, tying, and protection methods. Compliance with the appropriate class (Class 1 for general use, Class 2 for dedicated service, and Class 3 for high-performance/harsh environments) is the essential starting point for any quality control for cable assemblies system.

Quality management standards (ISO 9001) While ISO 9001 does not specify technical requirements for the cables themselves, its application is mandatory. A manufacturer certified under ISO 9001 ensures that its quality management processes, including design, documentation, and traceability, are defined, auditable, and subject to continuous improvement.

Sector-specific standards High-reliability industries impose additional layers of demand:

- Automotive (IATF 16949): Focuses on defect prevention and the reduction of variation and waste in the supply chain, mandating strict documentation via PPAP (Production Part Approval Process).

- Aerospace and defense (AS9100): Requires an extremely high level of traceability and material control, where assembly integrity is directly proportional to mission safety.

- Medical (ISO 13485): Demands that manufacturing processes maintain rigorous control conditions to ensure sterility and critical functionality in life-support devices. Adherence to all these sector-specific standards is the gold standard for quality control for cable assemblies.

Essential types of quality tests

A comprehensive quality control for cable assemblies system relies on the systematic application of electrical, mechanical, and environmental tests that simulate, and often exceed, real operational conditions.

Electrical tests

- Continuity and load testing: A harness tester is used to verify that every conductor is connected to the correct point and that there are no missing or crossed connections.

- High potential test (Hi-Pot): This is the quintessential safety test. It applies a voltage significantly higher than the operating voltage to ensure the cable’s insulation is effective and that no current leakage or electrical arcing will occur, guaranteeing the safety of the equipment and the operator. The reliability of these specialized assemblies depends on consistent quality control for cable assemblies.

- Insulation resistance: Measures the capacity of the dielectric material (the insulator) to resist current flow, ensuring the wiring will maintain signal integrity over time.

Mechanical tests

- Pull-test (Tensile strength): Measures the minimum force required to separate the metal terminal from the conductor. This test is vital because it ensures the crimp was executed with the correct pressure, guaranteeing the cable will not detach due to vibration or traction during its useful life.

- Vibration and shock tests: Assemblies are mounted on vibrating platforms to simulate the stress of transportation or operational conditions (e.g., a vehicle engine). Functionality and physical integrity are verified after being subjected to intense vibrations or sudden shocks.

Environmental tests

- Thermal cycling: This exposes the assembly to rapid and repeated temperature changes (e.g., from -40°C to +125°C). This verifies that the different materials (copper, plastic, insulators, connectors) do not expand or contract incompatibly, which could lead to cracks or crimp failures over time.

Ways to check the quality of cable assemblies

Effective quality control for cable assemblies encompasses both testing automation and specialized human intervention, serving as the first line of defense against defects.

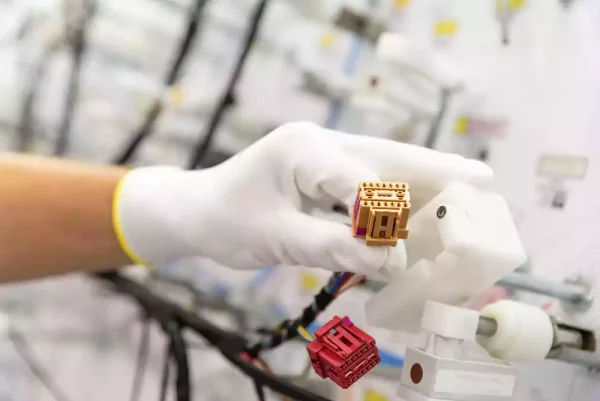

Detailed visual inspection Visual inspection, performed by personnel certified under the IPC/WHMA-A-620 standard, is irreplaceable. Inspectors look for macroscopic and microscopic defects:

- Crimping: Examination of a clean cut, the absence of stray strands, correct insulation exposure, and the proper formation of the crimp barrel.

- Wiring and routing: Verification that cables are not pinched, that the bend radius is not too tight (which could damage the conductor or insulation), and that the internal routing of the harness matches the assembly specification.

Dimensional control and tolerances Precise dimensional verification is crucial. Fixtures and laser measuring tools are used to confirm that the overall harness length, distances between connectors, and positioning of breakouts adhere to exact tolerances. This ensures a “perfect fit” in the customer’s chassis, preventing stresses that could cause long-term failures.

Traceability and documentation Quality is only as good as its documentation. A quality control for cable assemblies process establishes detailed records that include: material lots used, manufacturing dates, electrical test results (pass/fail), and the identity of the operator who performed the final inspection.

To guarantee the supply chain in key geographies, a high-performance vendor providing a cable assembly in Arizona must demonstrate that this traceability is infallible and digitized.

The real cost of cutting corners: Why quality isn’t optional

It’s tempting for companies facing tight deadlines or budget pressure to simplify the control stages. However, ignoring rigorous quality control for cable assemblies is the most expensive mistake you can make, it flips the profit equation upside down.

Robust quality control isn’t a cost center; it’s a strategic value driver. Think of it as the most profitable insurance you can buy against operational, financial, and reputational risks. The future success of your high-tech product is directly proportional to your focus on quality control for cable assemblies.

We specialize in designing and manufacturing custom cable assemblies that not only meet IPC standards but are built to surpass the stringent requirements of automotive, medical, and aerospace applications. We guarantee your crucial components are transformed from a potential point of failure into a guaranteed asset.