We often take for granted that pressing a button turns on a light or starts a vehicle. Behind this apparent simplicity lies a complex network known as electrical systems. These systems are the silent infrastructure that makes almost everything possible, from a toaster to a space shuttle.

But what turns a pile of components into a functional and reliable system? The answer lies in an often underestimated element: precision cabling.

What is an electrical system, and what is its purpose?

An electrical system (or electrical network) is defined as an organized network designed to generate, transmit, distribute, control, and consume electrical energy in order to perform useful work.

Its primary function is to orchestrate the movement of power and information. It is not just simple wiring; it is a complete architecture composed of four interdependent elements:

- Source: The origin of energy (batteries, generators, solar panels).

- Conduction Paths: The wiring, that is, the network through which energy or signals flow (this is where the cable harness is vital).

- Loads: The devices that consume the energy to perform a task (motors, lights, computers).

- Controls: Elements that regulate or interrupt the flow (switches, relays, fuses, electronic control units or ECUs).

The utility of electrical systems is to transform energy. They allow the potential energy of a battery to be converted into movement, light, heat, or processable data, essentially bringing technology to life.

The vital functions of electrical systems

Electrical systems perform three essential functions that keep modern machinery running:

- Power distribution: This is the ordered supply of energy to each component according to its voltage and amperage needs. This is a critical function that requires precision to avoid overheating and failures.

- Signal transmission: In the digital age, the electrical network is the backbone of communication. It allows data to flow between sensors, microprocessors, and actuators at very high speeds, enabling real-time automation and control.

- Protection and control: They incorporate fuses, circuit breakers, and other safety mechanisms that monitor the load and quickly isolate any fault or short circuit to protect equipment and prevent accidents.

Where do we find these systems, and why are they necessary?

We can find electrical systems virtually everywhere we look. They are so fundamental that their proper functioning is synonymous with stability and progress:

- At home: From the network that powers lights and appliances to heating, ventilation, and security systems.

- In industry: Production lines, robotics, quality control systems, and heavy machinery rely on complex electrical systems for their automation.

- In transportation: Every vehicle (cars, trains, airplanes) has a sophisticated electrical system that manages everything from ignition to advanced driver-assistance systems (ADAS).

Without the proper design of these reliable electrical systems, modern life would simply stop. Telecommunications infrastructure, hospitals, and water and sanitation systems are fully dependent on electricity to operate safely and continuously. Therefore, they are not just a technological luxury, but a fundamental necessity for social and economic continuity.

The fundamental role of the wire harness

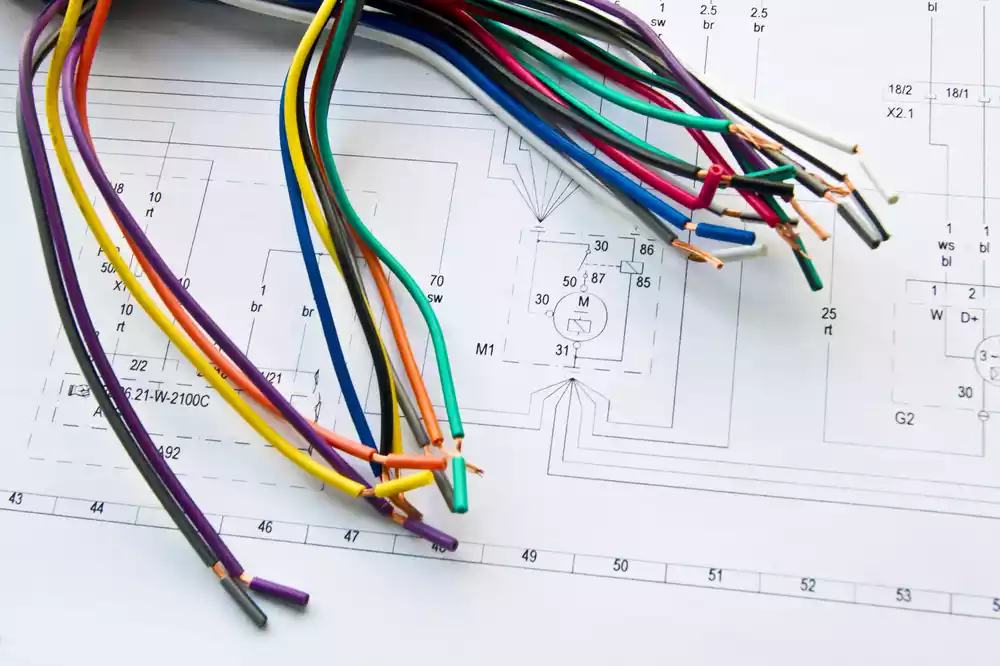

This is where the design and manufacturing of specialized cabling demonstrate their strategic value. Although individual wires are the conductors, the wire harness is the engineering element that ensures the network is manageable, safe, and robust.

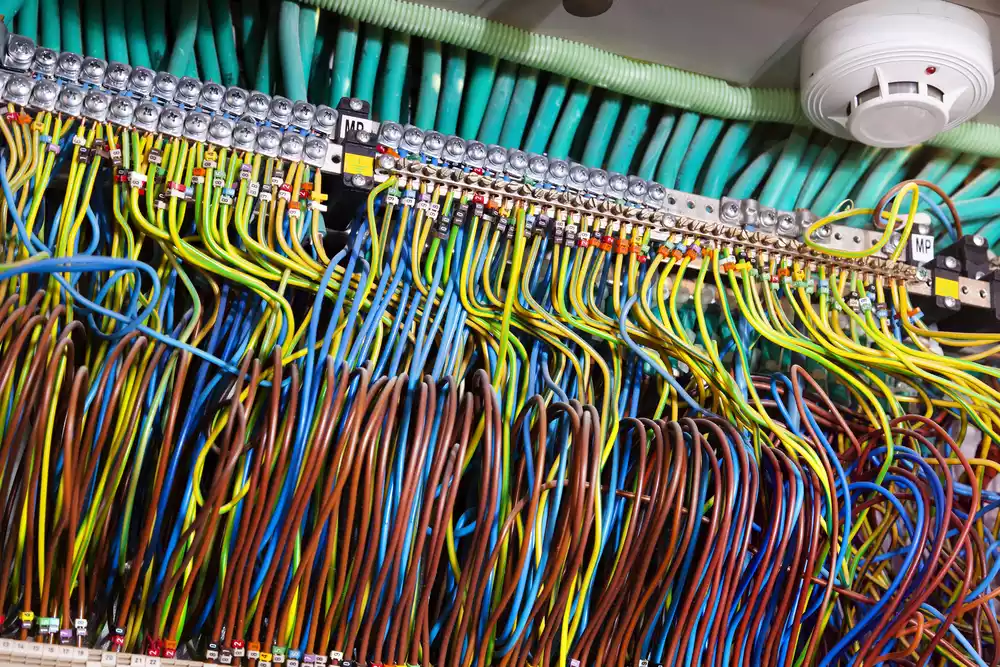

The wire harness assembly (assembled cable harness) groups dozens or even hundreds of wires, securing them with tape, sleeves, or conduits. This assembly plays a fundamental role for several reasons:

- Organization and space: It consolidates complex cable paths into a single compact unit, simplifying installation and freeing up critical space within a product or vehicle.

- Environmental protection: It provides critical defense against abrasion, moisture, vibration, and extreme temperature fluctuations. A loose cable could be damaged; a well-designed harness is prepared to withstand the working environment.

- Reduced assembly errors: Being pre-cut to the exact length and with specific terminals and connectors installed at the factory, it eliminates the possibility of a technician connecting a wire to the wrong place during final assembly.

- Signal integrity: The routing and shielding within the cable assembly are vital for reducing electromagnetic interference (EMI), ensuring that critical data signals are transmitted cleanly and quickly.

Industries benefiting from cabling quality

The quality of the cable harness directly impacts industries where failure is not an option:

- Automotive: The transition to electric vehicles (EV) and ADAS requires high-voltage harnesses and high-speed communication cables.

- Aerospace and Defense: Where weight, vibration resistance, and reliability are life-or-death parameters.

- Medical: In diagnostic and imaging equipment, the precision of the signal transmitted by the cable assembly is crucial for accurate results.

- Industrial Automation: Robots and CNC machinery rely on robust harnesses that withstand constant movement and aggressive factory environments.

Top 5 advantages of a well-produced electrical system

Producing high-quality electrical systems offers benefits that go beyond immediate performance, focusing attention on the quality of the cabling:

- Superior reliability and reduced downtime: A well-designed system with premium components is less likely to fail, maximizing product availability and reducing costly operational interruptions.

- Increased operational safety: Wiring with adequate insulation, gauge, and fuse protection minimizes the risk of catastrophic failures, such as fires, protecting both equipment and people.

- Optimized energy efficiency: Precise cabling design with low resistance minimizes voltage drop along the path, ensuring that the maximum amount of energy reaches the load. This is critical for EV range.

- Ease of maintenance and diagnosis: Cable harnesses are color-coded and labeled, allowing technicians to quickly identify circuits, shortening repair time and simplifying maintenance tasks.

- Longer product lifespan (Longevity): Robust materials and protection against wear ensure that the electrical system withstands the test of time, increasing the durability of the final product and offering a better return on investment to the consumer.

Trust IMA for your next-generation electrical systems

Understanding the complexity and vital role of electrical systems leads to one clear conclusion: your products demand the highest quality components. This is precisely where we at IMA stand out.

As an industry leader, we specialize in designing and manufacturing custom cable assemblies built to exceed the rigorous standards of automotive, medical, and aerospace applications. We guarantee that every harness we build provides the robust protection, perfect fit, and impeccable signal integrity your critical equipment needs.

Partner with us to transform your internal wiring from a potential point of failure into a guaranteed asset that enhances the safety, performance, and longevity of your products.