Think of your car, the life-saving MRI machine, or even the latest drone you saw flying. What do they all have in common? It’s not the engine, nor the touchscreen. It is a perfectly organized and hidden network of wires that allows every sensor to speak to its processor, every button to perform its task, and energy to flow without interruption. We call this network a cable harness, or wire harness, and its existence is, frankly, the reason technology works.

If a product is complex, its wiring is a potential chaos. The ability to control that chaos is where the true wire harness importance lies. It is the difference between a burnt-out circuit and a system that lasts a decade.

Definition and strategic function

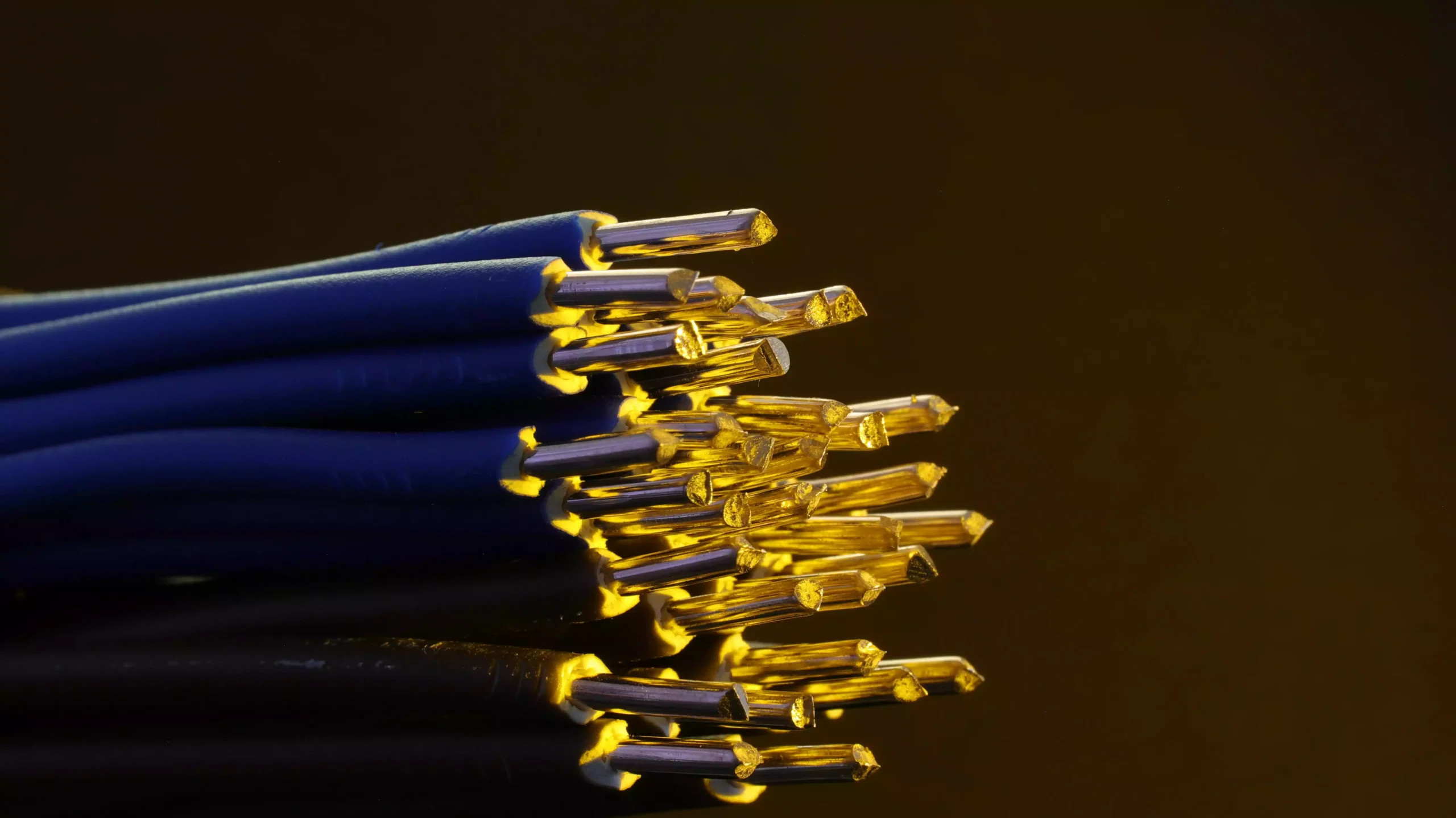

A wire harness is a structured, custom-designed matrix of electrical conductors (cables and wires) and terminal connectors, grouped and protected by insulating material, sheathing, or tape. Its primary objective is to provide precise electrical and data interconnection between multiple components within a predefined space.

The wire harness importance lies in its parametric design, which simultaneously addresses four engineering challenges:

- Signal Integrity (SI): Minimizing cross-talk and electromagnetic interference (EMI) through optimized routing and shielding.

- Environmental Protection: Offering mechanical resistance against abrasion, vibration, humidity, and thermal cycling.

- Reduction of Assembly Errors: Standardizing the installation process in large-scale production lines.

This manufacturing process, known as wire harness assembly, is governed by rigorous dimensional specifications, often validated by tooling and automated test benches that ensure the correct application of crimping force and electrical continuity. This dedication to precision underpins the foundational wire harness importance in overall product quality.

Systemic relevance in high-performance sectors

The wire harness’s importance is magnified in environments where tolerance for failure is zero.

- Automotive: In new-generation vehicles, harnesses must manage both high-speed data lines (Ethernet and CAN Bus) for infotainment and ADAS (Advanced Driver Assistance Systems), as well as high-voltage lines for electric vehicle (EV) battery systems.

- Aerospace and Defense: Here, weight and fatigue resistance are paramount. Harnesses must be lightweight to maximize fuel efficiency, yet robust enough to withstand extreme vibration and rapid changes in pressure and temperature.

- Industrial and Medical Equipment: The need to isolate sensitive instrumentation from ambient electrical noise makes shielding and material purity crucial to ensure exact measurements and patient safety.

For the manufacturer, the implementation of optimized wire harnesses reduces cycle times and variability in assembly, which translates directly into an improvement in OEE (Overall Equipment Effectiveness) and a decrease in warranty claims due to electrical failures. The efficiency gains delivered by superior design further solidify the wire harness importance as a key competitive factor.

Analysis of wire harness importance: Five vectors of reliability

The transcendence of this component can be broken down into the following engineering criteria:

- Mechanical Fatigue Mitigation: The design incorporates strain relief and tie-down points that distribute tension and vibration forces along the harness, protecting the most vulnerable points: the connector terminations.

- Quality Assurance (QA): By consolidating hundreds of connections into a single unit, the final testing process can be automated and executed in one step, using harness testers to verify continuity, insulation, and resistance, a key factor in the wire harness importance of serial production.

- Thermal and Spatial Optimization: Grouping allows engineers to precisely model heat dissipation (cable derating) and design routing to avoid high-temperature zones, maximizing packing density without compromising performance.

- EMC/EMI Compliance: Through the use of braided or foil shielding around sensitive cable groups, the harness acts as a localized Faraday cage, controlling both the emission and susceptibility to electromagnetic interference.

- Component Traceability: High-level manufacturers use data management systems to track the batches of wires and connectors used in each harness, allowing for rapid identification and isolation of issues in the event of a quality alert, reinforcing the wire harness importance in quality control.

The current state: Miniaturization and high density

The wire harness market is currently defined by the response to harness complexity driven by smart systems. The dominant trend is miniaturization, where smaller gauge wires (higher AWG) and thinner insulation are used to reduce weight and volume without sacrificing current capacity.

Simultaneously, the wire harness importance is being redefined with the rise of shielded twisted pair (STP) cables and fiber optic solutions for hybrid harnesses, critical for handling the gigabits-per-second data speeds required by current sensors and processors.

Future projection: Towards smart wire harnesses

The future of the wire harness focuses on functionalization and active monitoring.

- High-Voltage Systems (EVs): Development will focus on integrating arc flash protection and multiplexing solutions to reduce the physical number of conductors required in battery platforms.

- Detection and Integration (Autonomous): Harnesses will be the primary conduit for the vast data stream generated by LiDAR sensors and artificial intelligence. Data transfer reliability is the new primary metric of wire harness importance.

- IoT-Enabled Harnesses: The next generation of harnesses will incorporate temperature and pressure sensors within their insulation structure. This will enable real-time predictive health monitoring of the harness, detecting incipient failures (such as insulation degradation or strain) before they become critical failures, elevating the wire harness importance from passive to active.

IMA’s leadership and strategic advantage in the global industry

At IMA, we are taking bold steps into the future, preparing our infrastructure for the coming evolution in wire harness manufacturing. Our leadership is founded on quality management that transcends minimum specifications, strategically positioning us in high-level supply chains for sectors such as electric mobility, advanced robotics, and critical medical devices.

Our operational practices grant us a fundamental competitive advantage in the wire harness value chain, ensuring:

- Market Dominance and Global-Scale Capability: We possess a robust productive infrastructure and a distribution network that allows us to efficiently meet massive demands, maintaining product uniformity and quality internationally. This translates into a cost advantage and high availability for all our customers.

- Sustained Investment in R&D and Technological Adaptability: We maintain a constant cycle of reinvestment in the research and development of new materials, processes, and interconnection systems. This culture of innovation enables us to anticipate market trends and quickly adapt our solutions to emerging needs, such as high voltage or miniaturization.

- Solid Architecture of Customer Relationships and Trust: Our focus is not just on the product but on establishing long-term strategic partnerships with our clients. We offer specialized technical support and design consulting that makes us an integral partner, not just a supplier, increasing loyalty and the barrier to entry for the competition.

By prioritizing these world-class practices, IMA not only meets current technical specifications but is positioned to lead the evolution of wire harnesses toward smarter and more functional solutions internationally.