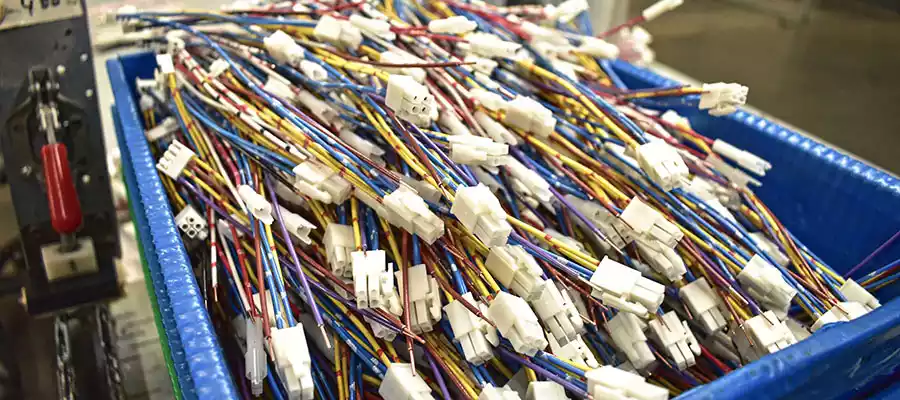

Every component, no matter how small, has a significant impact on a company’s success or failure. The cable assembly impact, often overlooked as a simple production process, is in reality a strategic factor that can determine a company’s efficiency, cost, and capacity for growth. The proper management of cable assembly can catapult a company, while poor execution can stall its development and jeopardize its reputation.

We will analyze how cable assembly impacts sales, cost structure, and production capacity, and why a high-quality design can be the key to market expansion and leadership.

Impact on sales and pricing

The design and production of a cable assembly have a direct influence on sales. A high-quality assembly results in a more reliable, durable, and superior-performing final product. This not only improves customer satisfaction but also reduces failures, returns, and warranty claims.

Customers are willing to pay more for products that promise consistent performance and a longer lifespan, which raises the perceived value of the product and differentiates it from the competition.

On the other hand, a low-quality design can lead to connection issues, intermittent failures, or even catastrophic failures. This not only affects brand reputation but can also result in a long-term loss of market share. Additionally, a well-designed assembly optimizes production efficiency. Less assembly time, a reduction in errors, and ease of installation allow companies to manufacture more products in less time. This efficiency directly translates to reduced costs and the possibility of offering more competitive prices, which is crucial in price-sensitive markets.

- Cost reduction: An optimized cable assembly design minimizes material waste and reduces the complexity of the assembly process, lowering manufacturing costs and allowing the company to be more profitable.

- Profit margin: An efficient and high-quality assembly allows companies to maintain or even increase their prices without losing competitiveness, which increases the profit margin and the long-term viability of the business.

- Brand positioning: The quality of the assembly is directly perceived in the performance and durability of the final product. A reliable and high-performing product reinforces the company’s image as a leader in quality and innovation, generating customer loyalty.

Design: The engine of growth

A strategic cable assembly design is a catalyst for business growth. If the design is robust and intelligently planned, a company can scale production quickly and smoothly. The use of standardized components and a modular structure facilitates the expansion of production to different plants or outsourcing. This allows the company to respond quickly to increased market demand without sacrificing quality.

However, if the necessary resources or experience for this process are lacking, growth can turn negative. A poor design can lead to production problems, bottlenecks, and failures, which result in costly delays in deliveries, loss of contracts, and the need to redesign the entire system, consuming valuable time and resources. The negative cable assembly impact of a bad design may cause a company to lose the opportunity to enter new markets or participate in large-scale projects.

-

Scalable production:

A modular and standardized design allows for increased production without compromising quality, facilitating organic growth and expansion.

-

Competitive advantage:

Companies that invest in designing high-quality assemblies gain a significant competitive advantage by offering more reliable and efficient products, which helps them stand out in the market.

-

Risks of poor execution:

Poor execution can generate costly delays, product rejections, recalls, and damage to reputation, which can be difficult to reverse.

Industries with the highest growth

Numerous industries have experienced significant growth by leveraging a well-designed cable assembly. The demands for performance, miniaturization, and reliability in these industries highlight the significant cable assembly impact, turning it into a critical component.

-

Automotive:

The automotive industry has been transformed by electrification and the integration of advanced driver-assistance systems (ADAS). A high-quality cable assembly is essential to manage the complexity of these systems, reduce vehicle weight to improve fuel efficiency, and ensure passenger safety.

-

Medical Devices:

In this industry, precision and reliability are vital. Cable assemblies for medical equipment, such as Magnetic Resonance Imaging (MRI) scanners or patient monitoring devices, must meet rigorous standards and be resistant to sterilization and electromagnetic interference. A quality assembly allows these companies to develop smaller and more precise equipment that can save lives.

-

Aerospace and Defense:

In this sector, weight and reliability are critical factors. Cable assemblies must be lightweight yet extremely resistant to vibrations and extreme temperature changes. An optimal design reduces the total weight of aircraft and ensures mission safety, leading to superior performance and lower operating costs.

-

Consumer Electronics:

As electronic devices become more compact and powerful, cable assembly has become a crucial component for optimizing internal space and heat dissipation, allowing for the creation of more elegant and functional products.

The role of quality standards and certifications

In today’s global context, a company’s success depends not only on the quality of its product, but also on its ability to demonstrate that this quality is consistent and verifiable. This is where quality standards and certifications play an indispensable role. The overall cable assembly impact of these standards is huge.

-

ISO Standards:

ISO certifications, such as ISO 9001, are fundamental. This standard focuses on quality management systems and ensures that a company’s processes are consistent and oriented toward continuous improvement. Obtaining this certification not only improves internal efficiency, but is also a powerful marketing tool that builds customer trust by demonstrating a commitment to quality on a global level.

-

Industry Standards:

In addition to general standards, specialized industries, such as cable assembly, have their own standards. A key example is IPC/WHMA-A-620, which establishes the requirements and acceptance criteria for cable and wire harness assemblies. Compliance with this standard ensures that the final product is reliable, robust, and safe for its intended use. This certification is often a requirement to work with high-level clients in the automotive, medical, and aerospace industries.

Investing in these certifications is a strategic decision that allows companies to differentiate themselves in the market, access highly regulated industries, and build long-term relationships based on trust and quality.

An investment in quality design, adherence to industry standards, and the choice of the right resources for cable assembly in Nevada can open doors to new markets, increase production efficiency, and ultimately drive sustainable and profitable growth.