Precision and efficiency are the pillars of success. Within industries ranging from automotive to medical, the creation of a wire harness is a complex process that depends directly on the quality of the tools used. Far from being simple accessories, the right tools become strategic assets that not only improve the quality of the final product but also optimize productivity and ensure safety. Choosing the correct tools for each task is a crucial decision that can define a company’s competitiveness.

Three indispensable tools for wire harness assembly

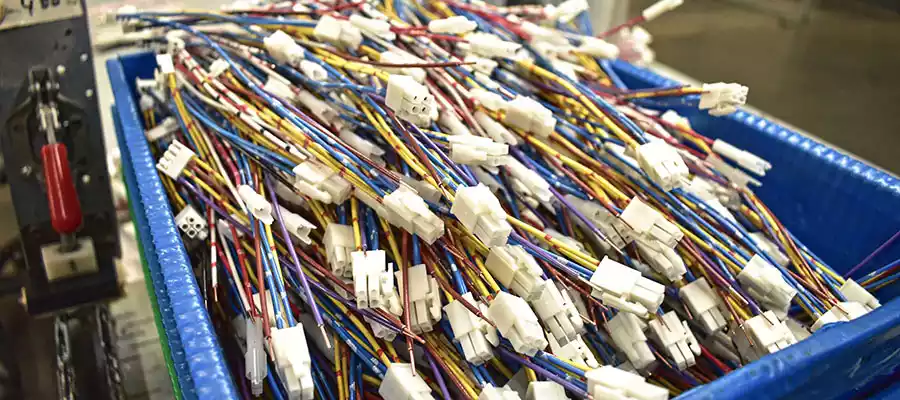

Wire harness assembly is an art that combines engineering, precision, and manual dexterity. To master it, it is essential to have an arsenal of wire harness assembly tools that allow each step to be performed with maximum quality. While the list of tools is extensive, three stand out for their fundamental role: crimping tools, wire strippers, and test stations.

1. Crimping tools

Crimping is the process of mechanically joining a connector to a wire, creating a secure and reliable electrical and mechanical connection. A high-quality crimping tool is, without a doubt, one of the most critical wire harness assembly tools.

A well-calibrated manual crimper is ideal for low volumes or specialized applications, while semi-automatic or automatic crimping machines are indispensable for mass production. The main function of these tools is to ensure that the clamping force is adequate, preventing loose connections that could fail or, conversely, excessive crimping that could damage the wire conductor.

2. Wire strippers

Before crimping, the wire’s insulation must be removed cleanly and precisely. A wire stripper is one of the most basic wire harness assembly tools, but its importance is immense. An incorrect strip can damage the conductor’s strands, compromising the connection’s integrity. Manual wire strippers are versatile, but for large-scale production, automatic cutting and stripping machines guarantee a uniform strip length and consistent quality across thousands of wires, minimizing errors and the need for rework.

3. Assembly boards and test stations

While not tools in the traditional sense, assembly boards (harness boards) are the blueprint and guide for the wire harness. These boards, often equipped with cable ties, guides, and templates, ensure that the shape, lengths, and connections of each harness are identical. Their role as wire harness assembly tools is crucial for reproducibility and standardization. Once assembled, the test station is responsible for verifying electrical continuity and correct connectivity, detecting any errors, before the final product is shipped.

How the right tools improve production

The adoption of the correct wire harness assembly tools has a direct and measurable impact on production. Beyond simply facilitating work, these tools are catalysts for continuous improvement in the value chain.

- Increased efficiency: Automated tools, such as cutting and stripping machines, can process hundreds or thousands of wires in the time it would take a manual tool to process just a few. This speed drastically reduces production times and increases overall output.

- Improved quality and consistency: The use of precision tools and calibrated machines ensures that each wire harness is manufactured to the exact specifications. This eliminates the variations inherent in manual work, resulting in a more reliable and high-quality product. Consistency is key to brand reputation and to reducing defect rates.

- Reduced operating costs: Although the initial investment in high-end wire harness assembly tools can be significant, the long-term savings are considerable. The reduction of errors, decreased production time, and minimization of material waste translate into a significant decrease in operating costs.

- Operator safety: Modern tools are designed with operator safety in mind. Ergonomic mechanisms and protection systems minimize the risk of injury, creating a safer and more productive work environment.

Manufacturing sectors that use these tools

The need for precise and reliable cable assembly is universal in modern manufacturing. Wire harness assembly tools are fundamental in sectors where the performance and safety of the final product are non-negotiable.

- Automotive industry: Modern vehicles are essentially computers on wheels. Every function, from the engine to the infotainment system, is controlled by complex wire harnesses. Precision is vital for vehicle safety and performance.

- Medical devices: In the medical sector, a wiring failure can have catastrophic consequences. Diagnostic imaging equipment, monitoring devices, and surgical instrumentation require maximum reliability. Wire harness assembly tools here must guarantee impeccable consistency and comply with strict regulations.

- Consumer electronics and aerospace: From the devices we use daily to the control systems of an aircraft, electronics depend on robust wiring. In the aerospace sector, weight, durability, and resistance to vibration are critical factors achieved through meticulous assembly.

How IMA can help you with your assembly

At IMA, we understand that choosing the correct wire harness assembly tools is only part of the equation. The true competitive advantage lies in experience, technology, and the manufacturing process. We position ourselves as your strategic partner, offering complete solutions that go beyond simply using the right tools.

We have a strategic location, top-tier machinery, and years of manufacturing experience. Our vast trajectory in the automotive, medical, and electronics sectors has given us a unique perspective on the needs of each industry. At IMA, we combine expert knowledge with the latest technology in wire harness assembly tools to ensure your projects are completed with maximum quality and efficiency.

We are ready to be your trusted partner, providing not only products but solutions that adapt to your specific needs. Whether you are looking to optimize your costs, improve your product’s quality, or reduce delivery times, our experience and team are at your disposal to help you achieve your goals.

Are you looking for a trusted partner for your assembly projects? Contact us today to learn more about how we can optimize your wire harness assembly and take your products to the next level.